Introduction to Upward suction chamber pump, how much is the price of the bin pump?

Upward suction chamber pumpis a kind of equipment used for pneumatic conveying, which is mainly used to convey powdery or granular materials to designated places through airflow.,at the start of the operation,When the material enters the pump body and is full, it is gasified to make the material form a fluidized state and smoothly enter the mixing chamber. At the same time, the compressed air is ejected at high speed through the jet nozzle and fully mixed with the fluid material. The high-speed airflow drives the material to pass through a specific pipeline, which converts the kinetic energy of compressed air into pressure energy, and at the same time, the air and the material are mixed again, so as to improve the speed of the material and make it move forward along the conveying pipeline, thus achieving the purpose of conveying powdery materials.,is a kind of high quality and low price Upward suction chamber pump,it is widely used in electricity industry, Cement industry, chemical lines, Building materials industry and chemical lines,It can be used for environmental protection and dust removal, powder conveying, material handling, pneumatic ash conveying, pneumatic transport, environmental protection and dust removal and so on。

1、Brief introduction of Upward suction chamber pump

Upward suction chamber pumpalso known as sending tank, pneumatic conveying pump or bin pump, it is a pressure vessel that uses compressed air (or other inert gas) as power source.,is a Upward suction chamber pump,Cheap and high quality。

Upward suction chamber pump

2、Upward suction chamber pump advantage

The advantages of Upward suction chamber pump are as follows:

- Efficient transportation

- Good flexibility

- Simple operation

- High reliability

- Convenient maintenance

Can use compressed air and other power sources to transport loose materials such as powder and granule at a long distance and with high efficiency. The conveying capacity is large, which can meet the requirements of large conveying capacity and improve production efficiency.

It can be combined with other conveying equipment (such as pipelines, valves, etc.) to form a complete conveying system. The conveying mode is flexible and diverse, and it can be unloaded at a single point or at multiple points to meet different conveying requirements.

The operation is simple and convenient, and usually adopts automatic control mode, which is suitable for the actual needs of engineering. Automatic control can be realized by programming, which reduces manual operation and labor intensity.

Made of high-quality materials and advanced technology, it has high reliability and durability. In the harsh working environment, it can still maintain good working performance and ensure the continuity and stability of material transportation.

Compact structure, easy installation and maintenance. The wear and tear of all parts can be checked regularly, and the damaged parts can be replaced in time to ensure the normal operation of the equipment. The maintenance cost is relatively low, which is helpful to improve the economy and service life of the equipment.

Upward suction chamber pump

3、Upward suction chamber pump characteristics

Upward suction chamber pumpthe main features are environmental protection and energy saving, convenient maintenance, flexible layout, efficient transportation and high reliability,is based on hyde powder is carefully developed by hyde combined with advanced technology。

Upward suction chamber pump

4、Introduction of advantages of Upward suction chamber pump

Upward suction chamber pumps have the following advantages.

- High reliability

- Efficient transportation

- Environmental protection and energy saving

- Strong adaptability

- Simple operation

Made of high-quality materials and advanced technology, it has high reliability and durability. In the harsh working environment, it can still maintain good working performance and ensure the continuity and stability of material transportation.

Can use compressed air and other power sources to transport loose materials such as powder and granule at a long distance and with high efficiency. The conveying capacity is large, which can meet the requirements of large conveying capacity and improve production efficiency.

Adopt fully sealed and pollution-free transportation mode, which meets the requirements of environmental protection. During transportation, materials will not leak, thus avoiding environmental pollution and material waste. Compared with other transportation modes, the energy consumption of the Upward suction chamber pump is relatively low, which is helpful for energy saving and emission reduction.

Suitable for a variety of material types, such as powder, granular and other loose materials. The transportation distance is long, which can meet the transportation needs of different distances and different terrains. Upward suction chamber pumps of different models and specifications can be customized according to specific needs to adapt to different application scenarios.

The operation is simple and convenient, and usually adopts automatic control mode, which is suitable for the actual needs of engineering. Automatic control can be realized by programming, which reduces manual operation and labor intensity.

Upward suction chamber pump

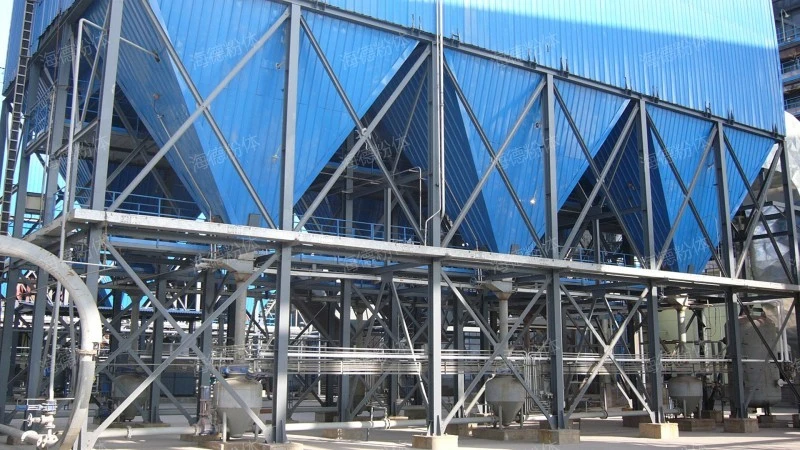

5、Upward suction chamber pump HD real picture

Overview of high-definition pictures,the product looks beautiful.。

Upward suction chamber pump

Note: All the pictures in this article were taken by hyde manufacturer.。

6、Structural characteristics of Upward suction chamber pump

The Upward suction chamber pump structure is introduced as follows:

- pump body

- Feed valve and discharge valve

- Air intake device

- pump body

- level-sensing device

The core part of the Upward suction chamber pump is used to contain materials. The pump body is generally a cylindrical pressure vessel, and its material is usually carbon steel or stainless steel to ensure sufficient strength to withstand internal pressure. In the design, the volume of the pump body should be considered, which will be determined according to the actual delivery requirements.

The feed valve is used to control the material entering the pump body, and the discharge valve is used to control the material discharging from the pump body. These valves are usually ball valves, butterfly valves or gate valves, which require good sealing to prevent material leakage and gas leakage.

Comprises an air inlet pipeline, an air inlet valve and other components. The air inlet pipe is used to introduce compressed air into the pump body, and the air inlet valve can control the flow and pressure of compressed air. The performance of air intake device directly affects the conveying speed and efficiency of materials.

The core part of the Upward suction chamber pump is used to contain materials. The pump body is generally a cylindrical pressure vessel, and its material is usually carbon steel or stainless steel to ensure sufficient strength to withstand internal pressure. In the design, the volume of the pump body should be considered, which will be determined according to the actual delivery requirements.

Used to detect the material level in the pump body. Common level gauges include capacitive level gauges and ultrasonic level gauges. Through the material level gauge, the feeding amount can be accurately controlled to avoid the situation that the pump body is too full or the material is insufficient.

Upward suction chamber pump

Upward suction chamber pumpThe structure is novel, special, advanced, reasonable and scientific.,the main structure includes control system, intake valve, fluidizer, bleeder valve, air evacuation valve and so on,the main structure includes pump body, control system, air evacuation valve, fluidizer and bleeder valve,also known as sending tank, pneumatic conveying pump or bin pump.。

Related recommendation

-

What is a Transport of polyvinyl butyral? Introduction to the advantages, characteristics, and principles of the Pneumatic conveying equipment

2025-5-26 -

Introduction to Gypsum powder pneumatic conveying and Material conveying structure principle

2025-5-26 -

What is a HDSR200V Roots Vacuum Pump? Introduction to the advantages, characteristics, and principles of the blower

2025-5-26 -

Introduction to Transportation of refractory materials, Powder conveying advantages, characteristics and principles

2025-5-26 -

超导材料气力输送

2014-3-12 -

Introduction to High pressure pneumatic conveying, introduction to Material conveying advantages and characteristics

2025-5-26 -

Introduction to Food granule conveying system and pneumatic conveying system structure principle

2025-5-26 -

What is a Continuous pneumatic conveying pump? Introduction to the Working Principle of bin pump

2025-5-26 -

Introduction to Long distance pneumatic conveying system for ton bags and Material conveying structure principle

2025-5-26 -

What is a Anti corrosion and explosion-proof Roots blower? Roots Blower specifications, models, and parameters

2025-5-26