Introduction to Mobile warehouse type powder conveying pump, introduction to bin pump advantages and characteristics

Mobile warehouse type powder conveying pumpalso known as sending tank, pneumatic conveying pump or bin pump.。The following is to introduce the Mobile warehouse type powder conveying pump:

1、Brief introduction of Mobile warehouse type powder conveying pump

Mobile warehouse type powder conveying pumpalso known as sending tank, pneumatic conveying pump or bin pump, it is a pressure vessel that uses compressed air (or other inert gas) as power source.,the principle is simple.It is a part of positive pressure pneumatic ash removal system to transport loose materials such as powder and granule through pipelines in a long distance and with high efficiency.,was developed and designed by hyde powder。

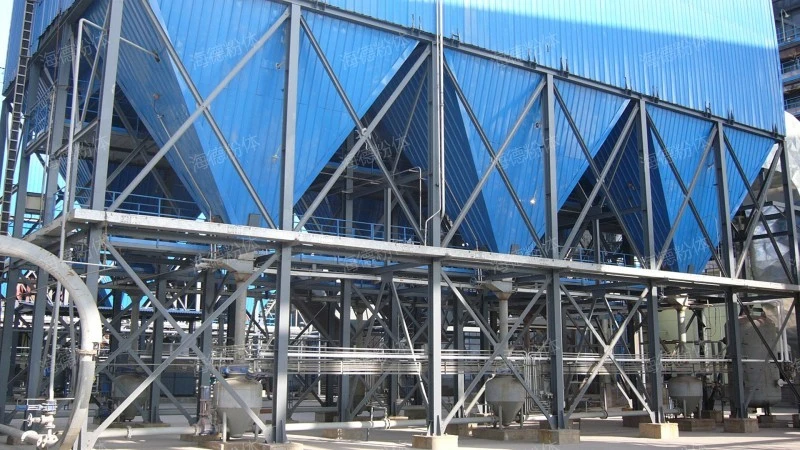

Mobile warehouse type powder conveying pump

2、Mobile warehouse type powder conveying pump introduction video

Speak directly with facts on the spot。

Mobile warehouse type powder conveying pump

As you can see from the live video.,Shandong Haide Fenti Engineering Co., Ltd. also called bin pump, it is a kind of positive pressure pneumatic conveying equipment.。

3、Working principle of Mobile warehouse type powder conveying pump

The Mobile warehouse type powder conveying pump has the following principles.

- Discharge stage

- Feeding stage

- Conveying stage

- Discharge stage

- Feeding stage

After the material is transported to the destination, it is discharged through the discharge valve. The destination can be a silo, a reaction kettle and other equipment for receiving materials. After discharging, the whole Mobile warehouse type powder conveying pump system can enter the next feeding-conveying-discharging cycle.

The feed valve of the Mobile warehouse type powder conveying pump is opened, and the material enters the pump body of the Mobile warehouse type powder conveying pump under the action of gravity or other feeding devices. In this process, the pressure inside the pump body is basically the same as the external atmospheric pressure to ensure the smooth entry of materials.

When the material in the pump body reaches a certain amount, the feed valve is closed. Then, introduce compressed air into the pump body. The compressed air expands rapidly in the pump body, so that the material is fully mixed with the air, and the material is pushed along the conveying pipeline under the action of air pressure.

After the material is transported to the destination, it is discharged through the discharge valve. The destination can be a silo, a reaction kettle and other equipment for receiving materials. After discharging, the whole Mobile warehouse type powder conveying pump system can enter the next feeding-conveying-discharging cycle.

The feed valve of the Mobile warehouse type powder conveying pump is opened, and the material enters the pump body of the Mobile warehouse type powder conveying pump under the action of gravity or other feeding devices. In this process, the pressure inside the pump body is basically the same as the external atmospheric pressure to ensure the smooth entry of materials.

Mobile warehouse type powder conveying pump

4、Working principle of Mobile warehouse type powder conveying pump

Mobile warehouse type powder conveying pumpWhen the material enters the pump body and is full, it is gasified to make the material form a fluidized state and smoothly enter the mixing chamber. At the same time, the compressed air is ejected at high speed through the jet nozzle and fully mixed with the fluid material. The high-speed airflow drives the material to pass through a specific pipeline, which converts the kinetic energy of compressed air into pressure energy, and at the same time, the air and the material are mixed again, so as to improve the speed of the material and make it move forward along the conveying pipeline, thus achieving the purpose of conveying powdery materials.。

Mobile warehouse type powder conveying pump

5、Mobile warehouse type powder conveying pump price concessions

The Mobile warehouse type powder conveying pump price is introduced as follows:

- select a qualified person

- company strength

- quality

- product function

- Quality advantages and disadvantages

The quality of materials directly determines the cost. The worse the materials are, the lower the cost will be, and the cheaper the price will be. Of course, the materials are better and the cost is higher, so the overall quotation is naturally higher.

Direct selling by manufacturers and sales by middlemen will also affect product prices. There are not too many links among direct selling products, so the cost required by manufacturers is low, and the price of Mobile warehouse type powder conveying pump is low. Customers can also put products into production in advance. On the contrary, when purchasing products from middlemen, there are not only many links, but also the price of Mobile warehouse type powder conveying pump is much higher, so customers should choose products directly sold by manufacturers when purchasing.

Quality is an important and fundamental factor that affects the price of Mobile warehouse type powder conveying pump. In the final analysis, its price depends on its quality. Usually, Mobile warehouse type powder conveying pump with better quality will cost more, and such products have better effects, longer service life and more advanced technology. A Mobile warehouse type powder conveying pump with a relatively general quality will cost less, have a shorter service life and have a relatively general use effect.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Quality is the key factor to determine the price. A high-quality product requires a lot of manpower, material resources and raw materials, so the manufacturing cost of the product is high. Therefore, the price of high-quality products is high. On the contrary, the price of Mobile warehouse type powder conveying pump is low.

Mobile warehouse type powder conveying pump

6、Company preferential activities

Mobile warehouse type powder conveying pump is a new type of bin pump introduced by hyde powder manufacturer, which has a wide range of applications, complete structural design and high working efficiency. It is an ideal equipment for food service industry and other industries. Now consult hydeproduce的Mobile warehouse type powder conveying pump, you can enjoy the discount, and there are many activities for you, such as full reduction and full reduction。

hyde powder

Mobile warehouse type powder conveying pumpThe overall structural design is relatively simple and compact.,the main structure includes intake valve, fluidizer, air evacuation valve, control system and air evacuation valve,is a Mobile warehouse type powder conveying pump,the product looks beautiful.。

Related recommendation

-

Introduction to Through star unloader, unloader specifications, model parameters

2025-5-26 -

Introduction to Fully automatic rotary feeder, how much is the price of the Feeder?

2025-5-26 -

纤维素气力输送案例

2014-3-14 -

What is a Magnesium sand pneumatic conveying equipment? Introduction to the principle of pneumatic conveying structure

2025-5-26 -

What is a Garbage automatic feeding and conveying equipment? Introduction to the advantages and characteristics of the pneumatic conveying

2025-5-26 -

Introduction to High temperature variable frequency star unloader and unloader advantages and features

2025-5-26 -

What is a Pearl sand powder conveying system? Introduction to the advantages, characteristics, and principles of the Powder conveying

2025-5-26 -

What is a Aquaculture aerator Lu's fan? How much is the price of the Roots Blower?

2025-5-26 -

What is a Silicon powder transportation? How much is the price of the Pneumatic conveying equipment?

2025-5-26 -

Introduction to Stainless steel Roots vacuum pump equipment and blower advantages and features

2025-5-26