Introduction to Central type pneumatic conveying bin pump, introduction to bin pump advantages and characteristics

Central type pneumatic conveying bin pumpas an efficient pneumatic conveying equipment,it is widely used inCement industry,food service industry,chemical lines,chemical lines,electricity industry and other industries,it is an ideal choice for customers to buy Central type pneumatic conveying bin pump。

1、Brief introduction of Central type pneumatic conveying bin pump

Central type pneumatic conveying bin pumpis a kind of equipment used for pneumatic conveying.,is designed by hyde with advanced technology。

Central type pneumatic conveying bin pump

2、Central type pneumatic conveying bin pump explanation video

You can buy Central type pneumatic conveying bin pump according to your needs and show you Central type pneumatic conveying bin pump videos.。

Central type pneumatic conveying bin pump

As you can see from the live video.,hyde multifunctional, with functions such as pneumatic ash conveying, material handling, pneumatic ash conveying, powder conveying and particle transport。

3、Advantages of Central type pneumatic conveying bin pump principle

The Central type pneumatic conveying bin pump has the following principles.

- Discharge stage

- Feeding stage

- Conveying stage

- Discharge stage

- Feeding stage

After the material is transported to the destination, it is discharged through the discharge valve. The destination can be a silo, a reaction kettle and other equipment for receiving materials. After discharging, the whole Central type pneumatic conveying bin pump system can enter the next feeding-conveying-discharging cycle.

The feed valve of the Central type pneumatic conveying bin pump is opened, and the material enters the pump body of the Central type pneumatic conveying bin pump under the action of gravity or other feeding devices. In this process, the pressure inside the pump body is basically the same as the external atmospheric pressure to ensure the smooth entry of materials.

When the material in the pump body reaches a certain amount, the feed valve is closed. Then, introduce compressed air into the pump body. The compressed air expands rapidly in the pump body, so that the material is fully mixed with the air, and the material is pushed along the conveying pipeline under the action of air pressure.

After the material is transported to the destination, it is discharged through the discharge valve. The destination can be a silo, a reaction kettle and other equipment for receiving materials. After discharging, the whole Central type pneumatic conveying bin pump system can enter the next feeding-conveying-discharging cycle.

The feed valve of the Central type pneumatic conveying bin pump is opened, and the material enters the pump body of the Central type pneumatic conveying bin pump under the action of gravity or other feeding devices. In this process, the pressure inside the pump body is basically the same as the external atmospheric pressure to ensure the smooth entry of materials.

Central type pneumatic conveying bin pump

4、Functional advantages of Central type pneumatic conveying bin pump

Central type pneumatic conveying bin pumps have the following advantages.

- Good flexibility

- High reliability

- Environmental protection and energy saving

- Convenient maintenance

- Strong adaptability

It can be combined with other conveying equipment (such as pipelines, valves, etc.) to form a complete conveying system. The conveying mode is flexible and diverse, and it can be unloaded at a single point or at multiple points to meet different conveying requirements.

Made of high-quality materials and advanced technology, it has high reliability and durability. In the harsh working environment, it can still maintain good working performance and ensure the continuity and stability of material transportation.

Adopt fully sealed and pollution-free transportation mode, which meets the requirements of environmental protection. During transportation, materials will not leak, thus avoiding environmental pollution and material waste. Compared with other transportation modes, the energy consumption of the Central type pneumatic conveying bin pump is relatively low, which is helpful for energy saving and emission reduction.

Compact structure, easy installation and maintenance. The wear and tear of all parts can be checked regularly, and the damaged parts can be replaced in time to ensure the normal operation of the equipment. The maintenance cost is relatively low, which is helpful to improve the economy and service life of the equipment.

Suitable for a variety of material types, such as powder, granular and other loose materials. The transportation distance is long, which can meet the transportation needs of different distances and different terrains. Central type pneumatic conveying bin pumps of different models and specifications can be customized according to specific needs to adapt to different application scenarios.

Central type pneumatic conveying bin pump

5、Central type pneumatic conveying bin pump principle

Central type pneumatic conveying bin pumpat runtime,When the material enters the pump body and is full, it is gasified to make the material form a fluidized state and smoothly enter the mixing chamber. At the same time, the compressed air is ejected at high speed through the jet nozzle and fully mixed with the fluid material. The high-speed airflow drives the material to pass through a specific pipeline, which converts the kinetic energy of compressed air into pressure energy, and at the same time, the air and the material are mixed again, so as to improve the speed of the material and make it move forward along the conveying pipeline, thus achieving the purpose of conveying powdery materials.,is an advanced Central type pneumatic conveying bin pump developed by our company in combination with the actual situation of the industry。

Central type pneumatic conveying bin pump

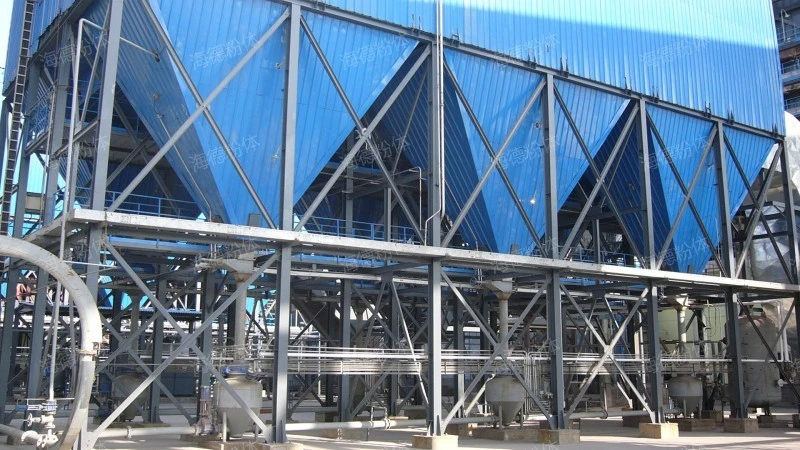

6、hyde powder delivery site

hyde provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the Central type pneumatic conveying bin pump production process and production site, and gain favorable comments and recognition from customers.。

Central type pneumatic conveying bin pump

As you can see from the live video.hyde powder at work,It is a part of positive pressure pneumatic ash removal system to transport loose materials such as powder and granule through pipelines in a long distance and with high efficiency.。

Central type pneumatic conveying bin pumpthe product looks atmospheric.,it is mainly composed of pump body, bleeder valve, control system, pump body and air evacuation valve。

Related recommendation

-

Introduction to Wool pneumatic conveying, Powder pneumatic conveying specifications, model parameters

2025-5-26 -

Introduction to Chloroprene rubber conveying, advantages, characteristics and principles of pneumatic conveying system

2025-5-26 -

Introduction to Cellulose transportation and Material conveying structure principle

2025-5-26 -

Introduction to Dust and ash pneumatic conveying equipment, how much is the price of the Pneumatic conveying equipment?

2025-5-26 -

What is a Automatic ingredient metering and conveying equipment? Powder conveying specifications, models, and parameters

2025-5-26 -

Introduction to Pharmaceutical factory transportation, Powder conveying specifications, model parameters

2025-5-26 -

What is a HDSR150V Roots Vacuum Pump? Roots Blower specifications, models, and parameters

2025-5-26 -

Introduction to Regenerated sand conveying equipment and pneumatic conveying system structure principle

2025-5-26 -

Introduction to ABS particle conveying and pneumatic conveying system working principle

2025-5-26 -

What is a Multi chamber pump pneumatic conveying? Introduction to the principle of pneumatic conveying structure

2025-5-26