Introduction to Oil free anti-corrosion Roots vacuum pump unit and blower working principle

Oil free anti-corrosion Roots vacuum pump unitis an efficient volumetric gas conveying and pressurizing equipment.,Simple structural design, stable and reliable operation and convenient maintenance. This enables it to maintain high working efficiency and stability in long-term operation.、It has high efficiency and can realize gas transportation and pressurization with low energy consumption.、Due to the adoption of synchronous gear transmission and small gap design, the Oil free anti-corrosion Roots vacuum pump unit runs stably and reliably, without contact and wear parts, and has a long service life.、The structural form of the three-blade rotor and the reasonable structure of the air inlet and outlet in the shell make the Oil free anti-corrosion Roots vacuum pump unit less vibration and noise.、Because of the design of three-blade rotor, the Oil free anti-corrosion Roots vacuum pump unit has little vibration and low noise during operation, and the operation is stable and reliable,at the start of the operation,The two three-blade impellers rotate relatively in the space sealed by the casing and the wallboard. Each impeller adopts the envelope of involute or epicycloid, the three blades of each impeller are exactly the same, and the two impellers are also exactly the same, which greatly reduces the machining difficulty. During the rotation of the impeller, air enters the air inlet cavity under the action of atmospheric pressure, and then two blades of each impeller, the wallboard and the casing form a sealed cavity. During the rotation of the impeller, the air in the air inlet cavity is continuously brought to the exhaust cavity by the sealed cavity formed by the two blades, and because the impellers in the exhaust cavity are meshed with each other, the air between the two blades is squeezed out, so that the air is continuously transported from the air inlet to the air outlet.,is a kind of high quality and low price Oil free anti-corrosion Roots vacuum pump unit,it is widely used in port, power, petrochemical industry, Textile light textile, chemical fertilizer and other industries。

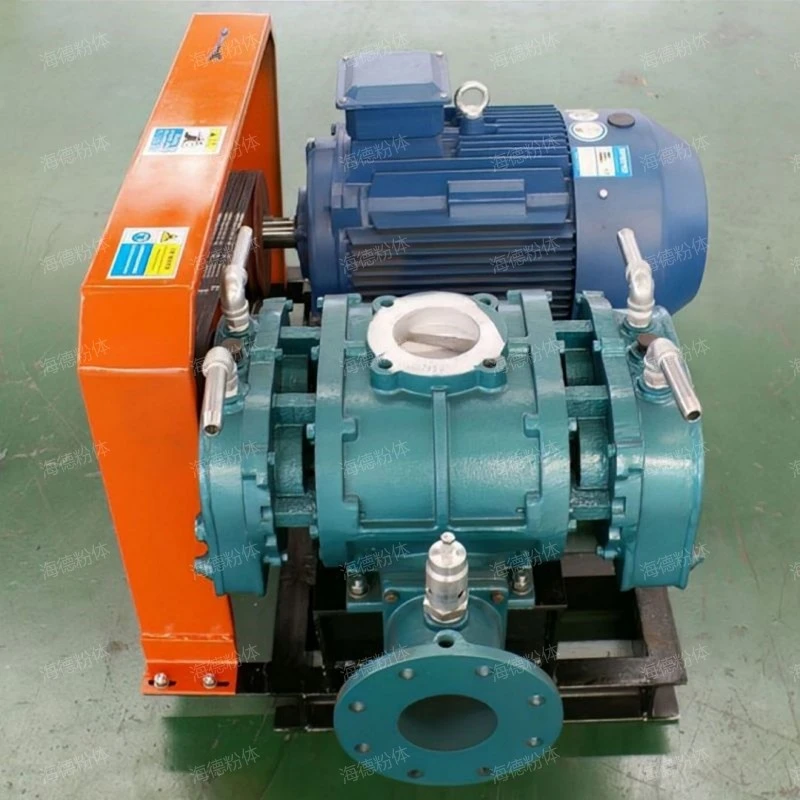

1、Brief introduction of Oil free anti-corrosion Roots vacuum pump unit

Oil free anti-corrosion Roots vacuum pump unitis a positive displacement blower with forced gas transmission characteristics.,Widely used in Desulfurization oxidation, sewage disposal, Pressurized transportation, exhaust emission and supply air,it has the functions of material fluidization, supply air, pick up the suction, cool and pressurized transportation,the advantage is The structural form of the three-blade rotor and the reasonable structure of the air inlet and outlet in the shell make the Oil free anti-corrosion Roots vacuum pump unit less vibration and noise.、Due to the adoption of synchronous gear transmission and small gap design, the Oil free anti-corrosion Roots vacuum pump unit runs stably and reliably, without contact and wear parts, and has a long service life.、In the process of air intake and exhaust, the Oil free anti-corrosion Roots vacuum pump unit will not produce air pulsation, which means that it does not need an additional buffer gas tank to output gas smoothly. This is particularly important for processes that require stable airflow.、The air volume is directly proportional to the rotating speed, so its air output is very stable and basically unaffected by pressure changes. This characteristic makes the Oil free anti-corrosion Roots vacuum pump unit perform well in many situations where stable airflow is needed.、It has high efficiency and can realize gas transportation and pressurization with low energy consumption.,be loved by our customers.。

Oil free anti-corrosion Roots vacuum pump unit

2、Oil free anti-corrosion Roots vacuum pump unit use

Oil free anti-corrosion Roots vacuum pump unitCommonly used inmaterial handling,mix,Material fluidization,dehydrate,pick up the suction and so on。

Oil free anti-corrosion Roots vacuum pump unit

3、Functional advantages of Oil free anti-corrosion Roots vacuum pump unit

Oil free anti-corrosion Roots vacuum pump units have the following advantages.

- Convenient maintenance

- Long service life

- Strong adaptability

- Durable performance

- Smooth operation

The structure of the Oil free anti-corrosion Roots vacuum pump unit is relatively simple and easy to maintain.

The mechanical friction of the Oil free anti-corrosion Roots vacuum pump unit is small and the loss is low, so its service life is relatively long. This enables it to maintain high working efficiency and stability in long-term operation.

Oil free anti-corrosion Roots vacuum pump units are suitable for many purposes and have been widely used in various fields.

The impeller and shaft of the Oil free anti-corrosion Roots vacuum pump unit are designed as a whole, and the impeller is not worn, so the performance is durable and can run continuously for a long time.

The structure form of the three-blade rotor and the reasonable structure of the air inlet and outlet in the shell make the fan have small vibration and low noise.

Oil free anti-corrosion Roots vacuum pump unit

4、Advantages of Oil free anti-corrosion Roots vacuum pump unit principle

Oil free anti-corrosion Roots vacuum pump unitin the course of work,Gas is compressed and transported based on the relative motion of two lobed rotors in the cylinder. When the two rotors rotate, the volume between them changes constantly, thus realizing the suction, compression and discharge of gas.,The overall structural design is relatively simple,it has the structure of muffler, muffler, case, bearing and fuel tank,the product looks atmospheric.,it is an ideal choice for customers to buy Oil free anti-corrosion Roots vacuum pump unit。

Oil free anti-corrosion Roots vacuum pump unit

5、Structural advantages of Oil free anti-corrosion Roots vacuum pump unit

The Oil free anti-corrosion Roots vacuum pump unit structure is introduced as follows:

- wallboard

- rotator

- impeller

- muffler

- fuel tank

It is mainly used to connect the casing with the impeller, support the rotation of the impeller, and play the role of end sealing.

The core components are two identical lobed rotors, which usually adopt involute or epicycloid envelope design to ensure close cooperation during rotation and reduce leakage.

It is the rotating part of the Oil free anti-corrosion Roots vacuum pump unit, which is divided into two leaves and three leaves. However, due to many advantages such as smaller air pulsation, less noise and smoother operation, the three-leaf Oil free anti-corrosion Roots vacuum pump unit has gradually replaced the two-leaf Oil free anti-corrosion Roots vacuum pump unit.

Used to reduce the noise caused by airflow pulsation when the Oil free anti-corrosion Roots vacuum pump unit enters and exits.

Mainly used for storing lubricating oil used for lubricating gears and bearings. The oil tank is used to store lubricating oil to lubricate bearings and gears and reduce wear and friction.

Oil free anti-corrosion Roots vacuum pump unit

6、How to choose the right product manufacturer?

Choosing a suitable Oil free anti-corrosion Roots vacuum pump unit manufacturer requires comprehensive consideration of many aspects. First of all, we should examine the strength of manufacturers, including production capacity, R&D team and industry experience. Strong manufacturers can better ensure product supply and innovation ability. Secondly, product quality is the key, and it is evaluated by product certification, material selection and manufacturing process to ensure the durability of products. Product performance can not be ignored, so we should choose manufacturers with matching technical parameters, rich types and customized services according to actual needs. After-sales service is equally important. Professional and timely service team, perfect after-sales content and extensive service network can make users worry about nothing. In addition, market reputation is also an important reference. We can understand the reputation and status of manufacturers through customer evaluation, industry reputation and award-winning honor. Finally, it is necessary to analyze the price and cost performance, and on the premise of ensuring the quality and performance, choose a manufacturer with reasonable price and high cost performance, so as to purchase Oil free anti-corrosion Roots vacuum pump unit products that meet the demand and have good cost performance.。

hyde

Oil free anti-corrosion Roots vacuum pump unitis a double impeller synchronous compression machine, belonging to a positive displacement blower.,usually used in Dust removal, pneumatic transport, water treatment, make paper, smelt and other fields。

Related recommendation

-

Introduction to Electric variable frequency round mouth discharger, how much is the price of the unloader?

2025-5-26 -

Introduction to Explosion proof Three Leaf Roots Vacuum Pump, how much is the price of the blower?

2025-5-26 -

Introduction to Polyacrylamide transportation, Pneumatic conveying equipment advantages, characteristics and principles

2025-5-26 -

What is a Calcium carbide powder conveying system? How much is the price of the Pneumatic conveying equipment?

2025-5-26 -

Introduction to Carbon steel ash tank pneumatic conveying pump, AV pump specifications, model parameters

2025-5-26 -

What is a Negative pressure suction conveying equipment? Introduction to the advantages, characteristics, and principles of the Pneumatic conveying equipment

2025-5-26 -

Introduction to Powder pneumatic conveying system, Powder pneumatic conveying specifications, model parameters

2025-5-26 -

Introduction to Automatic metering mixed conveying system, advantages, characteristics and principles of Material conveying

2025-5-26 -

What is a Automatic quantitative conveying system? Introduction to the Working Principle of pneumatic conveying

2025-5-26 -

Introduction to Small bag unpacking pneumatic conveying equipment, introduction to Material conveying advantages and characteristics

2025-5-26