What is a Three leaf Roots vacuum pump for vacuum packaging? Introduction to the advantages and characteristics of blower functions

Three leaf Roots vacuum pump for vacuum packagingthe models are complete and can meet the needs of different users for different purposes.,Mainly used foraquaculture,sewage disposal,dry,supply air andPressurized transportation,Mainly used forexhaust emission,Desulfurization oxidation,dehydrate,aquaculture andsewage disposal,at work,It mainly depends on the relative movement of two lobed rotors (usually three-bladed impellers) in the cylinder to compress and transport gas.,is developed and improved by hyde powder。The following is to introduce the Three leaf Roots vacuum pump for vacuum packaging:

1、Brief introduction of Three leaf Roots vacuum pump for vacuum packaging

Three leaf Roots vacuum pump for vacuum packagingis an efficient volumetric gas conveying and pressurizing equipment.。

Three leaf Roots vacuum pump for vacuum packaging

2、Three leaf Roots vacuum pump for vacuum packaging application

Three leaf Roots vacuum pump for vacuum packagingIt can be used for pick up the suction, Material fluidization, cool, Ventilation, material handling, mix and so on,is a kind of high quality and low price Three leaf Roots vacuum pump for vacuum packaging,the models are complete and can meet the needs of different users for different purposes.,support customization。

Three leaf Roots vacuum pump for vacuum packaging

3、Structural advantages of Three leaf Roots vacuum pump for vacuum packaging

The Three leaf Roots vacuum pump for vacuum packaging has the following structure

- wallboard

- bearing

- impeller

- rotator

- bearing

It is mainly used to connect the casing with the impeller, support the rotation of the impeller, and play the role of end sealing.

It is used to support the rotation of the rotor and bear the weight of the rotor and the load during operation.

It is the rotating part of the Three leaf Roots vacuum pump for vacuum packaging, which is divided into two leaves and three leaves. However, due to many advantages such as smaller air pulsation, less noise and smoother operation, the three-leaf Three leaf Roots vacuum pump for vacuum packaging has gradually replaced the two-leaf Three leaf Roots vacuum pump for vacuum packaging.

The core components are two identical lobed rotors, which usually adopt involute or epicycloid envelope design to ensure close cooperation during rotation and reduce leakage.

It is used to support the rotation of the rotor and bear the weight of the rotor and the load during operation.

Three leaf Roots vacuum pump for vacuum packaging

4、Video analysis of Three leaf Roots vacuum pump for vacuum packaging

hyde provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the Three leaf Roots vacuum pump for vacuum packaging production process and production site, and gain favorable comments and recognition from customers.。

Three leaf Roots vacuum pump for vacuum packaging

As you can see from the live video.,Shandong Haide Fenti Engineering Co., Ltd. the product looks atmospheric.。

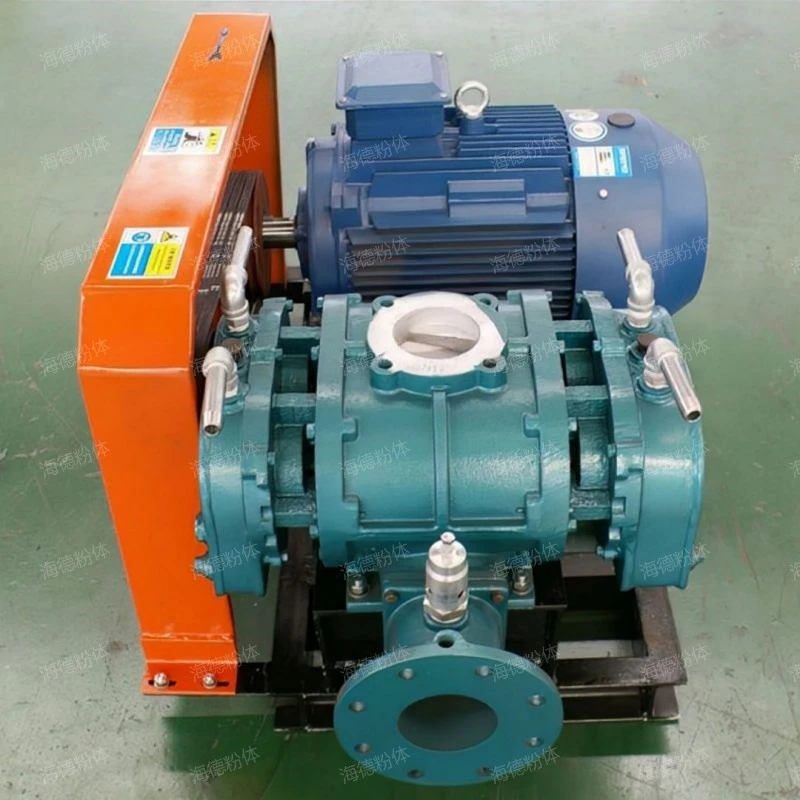

5、Three leaf Roots vacuum pump for vacuum packaging real shot picture

High-definition pictures of hyde powder Three leaf Roots vacuum pump for vacuum packaging, showing different specifications and models.。

Three leaf Roots vacuum pump for vacuum packaging

Note: All the pictures in this article were taken by hyde manufacturer.。

6、hyde powder's after-sales service

Perfect after-sales service is hyde's business policy. Our company has a professional after-sales service team, and all customer service personnel and maintenance technicians need pre-job training before they can take up their posts. Before the sale, there are customer service personnel to cooperate with customers to do a good job in product selection, and at the same time provide detailed information such as Three leaf Roots vacuum pump for vacuum packaging price and technical parameters; During the sale, sign a formal purchase contract with the customer and do a good job in product inspection to prevent leakage and delay the start-up time of the customer; After sale, we will provide customers with free transportation, installation and post-maintenance work. At the same time, we will pay regular return visits to the use of products. Once problems are found, we will send technicians to deal with them in time, and always keep the interests of customers doubled.。

hyde powder

Three leaf Roots vacuum pump for vacuum packagingWidely used in aeration, Ventilation, pick up the suction, exhaust emission and aquaculture,the main features are strong adaptability, stable and reliable, energy-efficient, low noise and durable performance,usually used in Food and beverage processing, pneumatic transport, power, petrify, Dust removal and other fields。

Related recommendation

-

What is a Clay conveying equipment? Introduction to the Working Principle of pneumatic conveying system

2025-5-26 -

What is a Sodium phosphate pneumatic conveying? Introduction to the Working Principle of Material conveying

2025-5-26 -

Introduction to HDSR-V Roots Vacuum Pump Equipment and blower structure principle

2025-5-26 -

What is a Pulse type silo pneumatic conveying pump? Introduction to the advantages and characteristics of bin pump functions

2025-5-26 -

What is a Bipolar series rotating feeder? How much is the price of the Feeder?

2025-5-26 -

What is a Pearlescent sand powder conveying? Introduction to the advantages and characteristics of Material conveying functions

2025-5-26 -

What is a Automatic weighing, measuring and conveying equipment? Powder pneumatic conveying specifications, models, and parameters

2025-5-26 -

Introduction to Step by step intermittent pneumatic conveying, advantages, characteristics and principles of Material conveying

2025-5-26 -

What is a Recycled sand transportation? Introduction to the principle of pneumatic conveying structure

2025-5-26 -

Introduction to Glass slag pneumatic conveying equipment, advantages, characteristics and principles of pneumatic conveying system

2025-5-26