Introduction to HDFB100 material sealing pump and Material seal pump advantages and features

HDFB100 material sealing pumpIt is a kind of equipment that uses the ejector effect of high-speed airflow to transport powdery materials.,it has been widely used in Cement industry, Alumina powder conveying, food, electricity industry, Aluminum industry and other industries,the product looks beautiful.。

1、Brief introduction of HDFB100 material sealing pump

HDFB100 material sealing pumpIt is a new type of pneumatic conveying equipment for powder, which belongs to the category of low-pressure dilute phase conveying, and mainly uses the ejector effect of high-speed airflow to convey powder materials.,Simple structure and advanced technology.,it is mainly composed of Bottom vaporization device, Nozzle adjusting device, Cylindrical pump body, Nozzle adjusting device and Cylindrical pump body,Commonly used inWaste disposal,Dust control,Conveying of powdery materials,System supporting use,Raw material transportation and so on,is a HDFB100 material sealing pump,the advantage is The pressure of ash conveying medium is low, the valve of equipment pipeline is not easy to wear, and the service life is long、The design is relatively simple, and there are no complicated mechanical structures and vulnerable parts, so it is very convenient to operate. The maintenance amount is small and the use cost is reduced.、It can be flexibly arranged and configured according to the specific conditions of the system to meet the transportation needs of different projects. Pipes can be arranged horizontally, vertically and obliquely, which is suitable for all kinds of complicated transportation scenes.、Using low-pressure conveying mode, the pressure of ash conveying medium is low, so the equipment pipes and valves are not easy to wear and prolong the service life.、Compared with the traditional mechanical conveying mode, the pneumatic conveying mode has higher energy efficiency ratio and lower energy consumption. The fully sealed design also reduces dust emission and is beneficial to environmental protection.。

HDFB100 material sealing pump

2、Functional advantages of HDFB100 material sealing pump

The advantages of HDFB100 material sealing pump are as follows:

- Simple structure and convenient operation and maintenance.

- Completely sealed and pollution-free.

- Continuous conveying

- Low pressure transportation, little wear and tear.

- Low pressure transportation, little wear and tear.

The design is relatively simple, and there are no complicated mechanical structures and vulnerable parts, so it is very convenient to operate. The maintenance amount is small, and the use cost is reduced.

By adopting low positive pressure and fully sealed transportation mode, foreign substances cannot enter the pipe, and the properties of the required materials will not be changed.

It can be continuously transported, and the transportation efficiency is improved.

The HDFB100 material sealing pump adopts low-pressure conveying mode, and the pressure of ash conveying medium is low, so the equipment pipes and valves are not easy to wear and prolong the service life.

The pressure of ash conveying medium is low, the valve of equipment pipeline is not easy to wear and has long service life.

HDFB100 material sealing pump

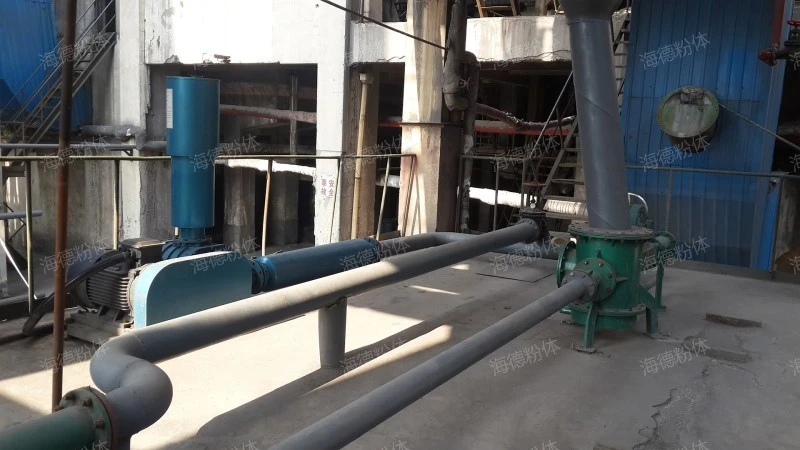

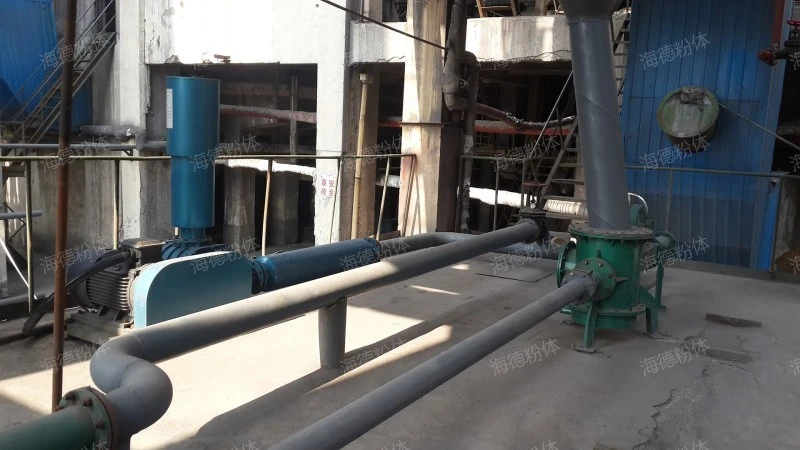

3、HDFB100 material sealing pump display

High-definition pictures for various HDFB100 material sealing pump, panoramic display,the product looks atmospheric., reliable in quality and trustworthy.。

HDFB100 material sealing pump

Note: All the pictures in this article were taken by hyde powder manufacturer.。

4、HDFB100 material sealing pump use

The purpose of HDFB100 material sealing pump is introduced as follows:

- Powder material conveying

- Supporting industrial production

- Waste treatment and reuse

- Dust control in environmental protection field

- Powder material conveying

The HDFB100 material sealing pump is mainly used for conveying all kinds of dry and loose powder materials, such as fly ash, alumina powder, dry kiln ash, limestone powder, cement powder and so on.

In medicine such as commodity industry, HDFB100 material sealing pumps can be used to transport all kinds of raw materials and finished products to improve production efficiency.

HDFB100 material sealing pumps can also be used in the field of waste treatment, such as conveying fly ash and other wastes for the production of environmentally friendly bricks or other recycling ways.

In the field of environmental protection, HDFB100 material sealing pumps play an important role. It can be used to collect and transport dust produced in industrial production process, thus effectively reducing dust pollution and improving working environment. In addition, the fully sealed design of the HDFB100 material sealing pump also prevents the leakage of dust and protects the surrounding environment.

The HDFB100 material sealing pump is mainly used for conveying all kinds of dry and loose powder materials, such as fly ash, alumina powder, dry kiln ash, limestone powder, cement powder and so on.

HDFB100 material sealing pump

5、Working principle of HDFB100 material sealing pump

HDFB100 material sealing pumpUsing high-speed airflow as power source, powder materials are transported from one place to another through the injection and carrying action of airflow.,Can be flexibly arranged and configured according to the specific situation of the system.、Compared with the traditional mechanical conveying mode, the pneumatic conveying mode has higher energy efficiency ratio and lower energy consumption. The fully sealed design also reduces dust emission and is beneficial to environmental protection.、It can be flexibly arranged and configured according to the specific conditions of the system to meet the transportation needs of different projects. Pipes can be arranged horizontally, vertically and obliquely, which is suitable for all kinds of complicated transportation scenes.、The design is relatively simple, and there are no complicated mechanical structures and vulnerable parts, so it is very convenient to operate. The maintenance amount is small and the use cost is reduced.、The low positive pressure and fully sealed conveying mode is adopted, which ensures that the powder will not leak to the external environment during the conveying process and meets the environmental protection requirements. The fully sealed design also prevents foreign substances from entering the tube, ensuring the purity and quality of the powder.,the product looks beautiful.,is carefully developed by hyde combined with advanced technology。

HDFB100 material sealing pump

HDFB100 material sealing pumpit has the characteristics of Wear is small, Small maintenance, Pollution-free transportation, Can be continuously conveyed. and Convenient and flexible layout,is a common HDFB100 material sealing pump。

Related recommendation

-

Introduction to Chili powder pneumatic conveying system and pneumatic conveying system working principle

2025-5-26 -

What is a Pneumatic conveying in electronic factories? Pneumatic conveying equipment specifications, models, and parameters

2025-5-26 -

Introduction to HDSR200 Three leaf Roots blower, how much is the price of the blower?

2025-5-26 -

Introduction to Lithium manganese oxide pneumatic conveying system and pneumatic conveying working principle

2025-5-26 -

What is a Calcium chloride delivery system? Introduction to the advantages and characteristics of the Material conveying

2025-5-26 -

What is a DN400 rotary discharger? unloader specifications, models, and parameters

2025-5-26 -

Introduction to Solid powder pneumatic conveying equipment and pneumatic conveying working principle

2025-5-26 -

Introduction to Automatic hybrid pneumatic conveying system, introduction to Powder pneumatic conveying function advantages and characteristics

2025-5-26 -

What is a Copper ore pneumatic conveying? Pneumatic conveying equipment specifications, models, and parameters

2025-5-26 -

What is a Transportation of ammonium nitrate containing water? Introduction to the advantages, characteristics, and principles of the Powder conveying

2025-5-26