What is a Powder pneumatic conveying material sealing pump? Introduction to the Working Principle of Material seal pump

Powder pneumatic conveying material sealing pumpIt is an advanced pneumatic conveying equipment for powder.,the principle is simple.Using the action of air jet, the air drives the ash particles to send the ash to ash storage. There are two main sources of energy, one is the kinetic energy of the fan, and the other is the potential energy of the material column. When the material column is high, the potential energy is high and the pressure is high, the conveying capacity is correspondingly large, and vice versa.,is a common Powder pneumatic conveying material sealing pump。The following is to introduce the Powder pneumatic conveying material sealing pump:

1、Brief introduction of Powder pneumatic conveying material sealing pump

Powder pneumatic conveying material sealing pumpIt is a device for conveying powdery materials by using the ejector effect of high-speed airflow.,the main features are Transport stability, Convenient and flexible layout, Pollution-free transportation, Wear is small and Reliable operation,is developed and improved by hyde powder。

Powder pneumatic conveying material sealing pump

2、Introduction of Powder pneumatic conveying material sealing pump characteristics

Powder pneumatic conveying material sealing pumpit has the characteristics of Small maintenance, Small maintenance, Wear is small, omniseal and easy to operate,multifunctional, with functions such as Raw material transportation, Conveying of powdery materials, Waste disposal, Waste disposal and System supporting use,It can be transported continuously, and the output of equipment can be automatically adjusted to achieve good ash conveying effect.、The design is relatively simple, and there are no complicated mechanical structures and vulnerable parts, so it is very convenient to operate. The maintenance amount is small and the use cost is reduced.、It can be flexibly arranged and configured according to the specific conditions of the system to meet the transportation needs of different projects. Pipes can be arranged horizontally, vertically and obliquely, which is suitable for all kinds of complicated transportation scenes.、By adopting the low positive pressure and fully sealed transportation mode, foreign substances can not enter the pipe and will not change the properties of the required materials.、Can be flexibly arranged and configured according to the specific situation of the system.,The overall structural design is relatively simple,generally, it is composed of Supporting and connecting parts, Bottom vaporization device, Cylindrical pump body, Cylindrical pump body, Nozzle adjusting device and other major components,The price is more affordable。

Powder pneumatic conveying material sealing pump

3、Powder pneumatic conveying material sealing pump application

Powder pneumatic conveying material sealing pumps have the following purposes.

- Environmental protection and dust control

- Powder material conveying

- Supporting industrial production

- Dust control in environmental protection field

- System integration and customization

In the field of environmental protection, Powder pneumatic conveying material sealing pumps can be used for dust collection and transportation, which helps to reduce dust pollution and improve the working environment.

The Powder pneumatic conveying material sealing pump is mainly used for conveying all kinds of dry and loose powder materials, such as fly ash, alumina powder, dry kiln ash, limestone powder, cement powder and so on.

In glass such as commodity industry, Powder pneumatic conveying material sealing pumps can be used to transport all kinds of raw materials and finished products to improve production efficiency.

In the field of environmental protection, Powder pneumatic conveying material sealing pumps play an important role. It can be used to collect and transport dust produced in industrial production process, thus effectively reducing dust pollution and improving working environment. In addition, the fully sealed design of the Powder pneumatic conveying material sealing pump also prevents the leakage of dust and protects the surrounding environment.

The Powder pneumatic conveying material sealing pump can also be used as a supporting equipment for large-scale pneumatic conveying system or powder treatment system, and work together with other equipment to realize automatic and continuous powder conveying.

Powder pneumatic conveying material sealing pump

4、Powder pneumatic conveying material sealing pump explanation video

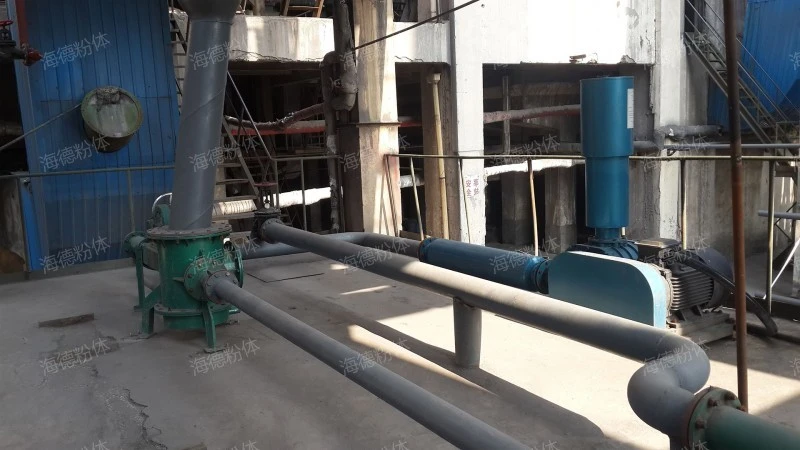

Speak directly with facts on the spot。

Powder pneumatic conveying material sealing pump

As you can see from the live video.,Shandong Haide Fenti Engineering Co., Ltd. It can be transported continuously, and the output of equipment can be automatically adjusted to achieve good ash conveying effect.、It can be flexibly arranged and configured according to the specific conditions of the system to meet the transportation needs of different projects. Pipes can be arranged horizontally, vertically and obliquely, which is suitable for all kinds of complicated transportation scenes.、The low positive pressure and fully sealed conveying mode is adopted, which ensures that the powder will not leak to the external environment during the conveying process and meets the environmental protection requirements. The fully sealed design also prevents foreign substances from entering the tube, ensuring the purity and quality of the powder.、Using low-pressure conveying mode, the pressure of ash conveying medium is low, so the equipment pipes and valves are not easy to wear and prolong the service life.、The design is relatively simple, and there are no complicated mechanical structures and vulnerable parts, so it is very convenient to operate. The maintenance amount is small and the use cost is reduced.。

5、Powder pneumatic conveying material sealing pump price advantage

The Powder pneumatic conveying material sealing pump price is introduced as follows:

- select a qualified person

- product function

- Model type

- Service factor

- Configuration difference

The quality of material selection is one of the main factors that directly affect the Powder pneumatic conveying material sealing pump. If the quality of material selection is better, the price may be more expensive. Therefore, customers must first understand the quality of material selection before purchasing products, and then compare whether the quality and price match.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The same product, with different specifications and models, requires different materials and accessories when manufacturing. Moreover, the products with different specifications and models have different performance, and the manufacturers have different production costs, so the prices of products with different specifications and models are also different.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, hyde Powder pneumatic conveying material sealing pump manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Powder pneumatic conveying material sealing pump price can meet the purchasing needs of customers.

Usually, the quotation of Powder pneumatic conveying material sealing pump changes with its configuration, but the quotation is different according to the different needs of customers and different product configurations.

Powder pneumatic conveying material sealing pump

6、company strength

The company has many years of Powder pneumatic conveying material sealing pump manufacturing experience, large scale and strong strength.。

hyde powder

Powder pneumatic conveying material sealing pumpIt is a new type of pneumatic conveying equipment for powder, which uses the ejector effect of high-speed airflow to convey powder materials.,in the course of work,Using high-speed airflow as power source, powder materials are transported from one place to another through the injection and carrying action of airflow.,is a popular Powder pneumatic conveying material sealing pump。

Related recommendation

-

What is a Carbon steel three leaf Roots blower? Introduction to the advantages and characteristics of Three leaf Roots blower functions

2025-5-26 -

Introduction to High air volume water-cooled three blade Roots blower and Three leaf Roots blower working principle

2025-5-26 -

What is a Copper sulfate conveying system? Introduction to the principle of Material conveying structure

2025-5-26 -

What is a Roots blower in the food industry? Introduction to the advantages and characteristics of the Roots Blower

2025-5-26 -

Introduction to High temperature fly ash pneumatic conveying system, introduction to pneumatic conveying system advantages and characteristics

2025-5-26 -

What is a Automatic bag breaking conveyor system? Introduction to the Working Principle of Material conveying

2025-5-26 -

Introduction to High temperature fine ash conveying system, advantages, characteristics and principles of pneumatic conveying

2025-5-26 -

What is a Polypropylene particle transportation? Introduction to the principle of Material conveying structure

2025-5-26 -

What is a Horizontal silo pneumatic conveying pump? Introduction to the principle of bin pump structure

2025-5-26 -

Introduction to Fully enclosed dust-free pneumatic conveying equipment, introduction to Powder pneumatic conveying function advantages and characteristics

2025-5-26