What is a Large particle conveying material sealing pump? How much is the price of the Material seal pump?

Large particle conveying material sealing pumpIt is a new type of powder pneumatic conveying equipment, belonging to the category of low-pressure dilute phase conveying.,it is widely used in food, Alumina powder conveying, Aluminum industry, building materials and glass。

1、Brief introduction of Large particle conveying material sealing pump

Large particle conveying material sealing pumpIt is a kind of powder pneumatic conveying equipment.,It has a wide range of uses, including Conveying of powdery materials, System supporting use, Dust control, Raw material transportation and Waste disposal。

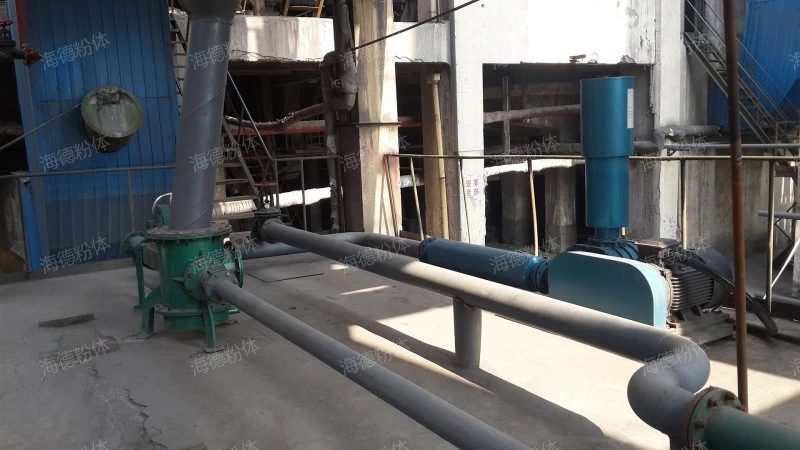

Large particle conveying material sealing pump

2、Introduction of Large particle conveying material sealing pump characteristics

Large particle conveying material sealing pumpit has the characteristics of be of simple construction, easy to operate, Reliable operation, Long service life and Simple operation,in the course of work,Using the action of air jet, the air drives the ash particles to send the ash to ash storage. There are two main sources of energy, one is the kinetic energy of the fan, and the other is the potential energy of the material column. When the material column is high, the potential energy is high and the pressure is high, the conveying capacity is correspondingly large, and vice versa.,is a Large particle conveying material sealing pump,By adopting the low positive pressure and fully sealed transportation mode, foreign substances can not enter the pipe and will not change the properties of the required materials.、The pressure of ash conveying medium is low, the valve of equipment pipeline is not easy to wear, and the service life is long、The low positive pressure and fully sealed conveying mode is adopted, which ensures that the powder will not leak to the external environment during the conveying process and meets the environmental protection requirements. The fully sealed design also prevents foreign substances from entering the tube, ensuring the purity and quality of the powder.、The design is relatively simple, and there are no complicated mechanical structures and vulnerable parts, so it is very convenient to operate. The maintenance amount is small and the use cost is reduced.、Using low-pressure conveying mode, the pressure of ash conveying medium is low, so the equipment pipes and valves are not easy to wear and prolong the service life.,it is mainly composed of injector, Bottom vaporization device, Nozzle adjusting device, Feed port and discharge port and Nozzle adjusting device。

Large particle conveying material sealing pump

3、Working principle of Large particle conveying material sealing pump

Large particle conveying material sealing pumpat work,Using the high-speed airflow generated by the nozzle, a negative pressure area is formed, thereby ejecting powder materials into the pump body. This ejector action enables the powder material to be carried by the airflow and transported.,it has the functions of Long-distance or complex terrain material transportation, Raw material transportation, Conveying of powdery materials, Waste disposal and Dust control,It is a new type of pneumatic conveying equipment for powder, which belongs to the category of low-pressure dilute phase conveying, and mainly uses the ejector effect of high-speed airflow to convey powder materials.,it is widely used in food, Cement industry, Processing industry, environmental protection, building materials and other industries,has been favored by more and more customers.。

Large particle conveying material sealing pump

4、Structural advantages of Large particle conveying material sealing pump

The Large particle conveying material sealing pump has the following structure

- Supporting and connecting parts

- Cylindrical pump body

- Supporting and connecting parts

- Nozzle adjusting device

- Bottom vaporization device

The supporting and connecting parts are used to support and connect various parts of the Large particle conveying material sealing pump to ensure the stability and integrity of the pump body. The design and manufacture of these components need to consider factors such as strength, stiffness and stability.

The cylindrical pump body is the main part of the Large particle conveying material sealing pump, which contains the nozzle and powder materials, and provides the necessary space for air flow and powder to be mixed and transported. The material and structure design of the pump body need to consider the factors such as wear resistance, corrosion resistance and sealing.

The supporting and connecting parts are used to support and connect various parts of the Large particle conveying material sealing pump to ensure the stability and integrity of the pump body. The design and manufacture of these components need to consider factors such as strength, stiffness and stability.

The nozzle adjusting device is used to adjust the air outlet volume and air outlet angle of the nozzle to adapt to different conveying requirements and powder characteristics. By adjusting the nozzle adjusting device, the conveying performance of the Large particle conveying material sealing pump can be optimized and the conveying efficiency and stability can be improved.

The bottom vaporizing device is an optional component in the Large particle conveying material sealing pump. It vaporizes the powder at the bottom of the pump body by steam or other vaporizing media to reduce the friction and wear between the powder and the pump body and improve the smoothness and efficiency of transportation.

Large particle conveying material sealing pump

5、Large particle conveying material sealing pump advantage

The advantages of Large particle conveying material sealing pump are as follows:

- Simple structure and convenient operation and maintenance.

- Low pressure transportation, little wear and tear.

- Continuous conveying

- Simple structure and convenient operation

- energy saving and environmental protection

The design is relatively simple, and there are no complicated mechanical structures and vulnerable parts, so it is very convenient to operate. The maintenance amount is small, and the use cost is reduced.

The pressure of ash conveying medium is low, the valve of equipment pipeline is not easy to wear and has long service life.

It can be transported continuously, and the output of equipment can be automatically adjusted to achieve good ash conveying effect.

The Large particle conveying material sealing pump has simple structure, convenient operation and small maintenance.

Compared with the traditional mechanical conveying mode, the pneumatic conveying mode has higher energy efficiency ratio and lower energy consumption.

Large particle conveying material sealing pump

6、Advantages of Large particle conveying material sealing pump principle

Large particle conveying material sealing pumpat the start of the operation,Using high-speed airflow as power source, powder materials are transported from one place to another through the injection and carrying action of airflow. In the process of pneumatic conveying, the interaction between airflow and powder materials makes the powder materials carried by airflow and transported along the pipeline.,features include omniseal, Wear is small, Transport stability, Convenient and flexible layout and Small maintenance。

Large particle conveying material sealing pump

Large particle conveying material sealing pumpis a common Large particle conveying material sealing pump,the advantage is It can be flexibly arranged and configured according to the specific conditions of the system to meet the transportation needs of different projects. Pipes can be arranged horizontally, vertically and obliquely, which is suitable for all kinds of complicated transportation scenes.、Can be flexibly arranged and configured according to the specific situation of the system.、Powder can be continuously conveyed, and the conveying efficiency is improved. The equipment has the function of automatically adjusting the output, which can adjust the conveying quantity according to the actual demand and achieve good ash conveying effect.、Compared with the traditional mechanical conveying mode, the pneumatic conveying mode has higher energy efficiency ratio and lower energy consumption. The fully sealed design also reduces dust emission and is beneficial to environmental protection.、It can be transported continuously, and the output of equipment can be automatically adjusted to achieve good ash conveying effect.。

Related recommendation

-

What is a Self suction dust removal pneumatic conveying system? Introduction to the advantages and characteristics of pneumatic conveying functions

2025-5-26 -

Introduction to Powder screening, mixing and conveying equipment, introduction to Powder conveying function advantages and characteristics

2025-5-26 -

What is a Three element positive electrode material pneumatic conveying system? Introduction to the advantages and characteristics of the pneumatic conveying system

2025-5-26 -

Introduction to High negative pressure Roots vacuum pump unit and blower structure principle

2025-5-26 -

What is a Three leaf Roots blower for sewage aeration and oxygenation? blower specifications, models, and parameters

2025-5-26 -

Introduction to Pneumatic conveying system for vinyl ester resin, Pneumatic conveying equipment advantages, characteristics and principles

2025-5-26 -

What is a Pressure fed bottom conveying pump? bin pump specifications, models, and parameters

2025-5-26 -

Introduction to Stainless steel silo bottom conveying pump, introduction to bin pump function advantages and characteristics

2025-5-26 -

Introduction to Ammonium bicarbonate pneumatic conveying system and pneumatic conveying structure principle

2025-5-26 -

Introduction to Measurement bin pump pneumatic conveying and pneumatic conveying system structure principle

2025-5-26