Introduction to Suction type pneumatic conveying bin pump and bin pump working principle

Suction type pneumatic conveying bin pumpis a kind of equipment used for pneumatic conveying, which is mainly used to convey powdery or granular materials to designated places through airflow.,at work,It is a part of positive pressure pneumatic ash removal system to transport loose materials such as powder and granule through pipelines in a long distance and with high efficiency.,is a kind of high quality and low price Suction type pneumatic conveying bin pump。The following is to introduce the Suction type pneumatic conveying bin pump:

1、Brief introduction of Suction type pneumatic conveying bin pump

Suction type pneumatic conveying bin pumpalso known as sending tank, pneumatic conveying pump or bin pump.,it has the functions of particle transport, powder conveying, material handling, pneumatic ash conveying and environmental protection and dust removal。

Suction type pneumatic conveying bin pump

2、Suction type pneumatic conveying bin pump performance advantage

Suction type pneumatic conveying bin pumps have the following advantages.

- Strong adaptability

- Convenient maintenance

- Good flexibility

- Simple operation

- Good flexibility

Suitable for a variety of material types, such as powder, granular and other loose materials. The transportation distance is long, which can meet the transportation needs of different distances and different terrains. Suction type pneumatic conveying bin pumps of different models and specifications can be customized according to specific needs to adapt to different application scenarios.

Compact structure, easy installation and maintenance. The wear and tear of all parts can be checked regularly, and the damaged parts can be replaced in time to ensure the normal operation of the equipment. The maintenance cost is relatively low, which is helpful to improve the economy and service life of the equipment.

It can be combined with other conveying equipment (such as pipelines, valves, etc.) to form a complete conveying system. The conveying mode is flexible and diverse, and it can be unloaded at a single point or at multiple points to meet different conveying requirements.

The operation is simple and convenient, and usually adopts automatic control mode, which is suitable for the actual needs of engineering. Automatic control can be realized by programming, which reduces manual operation and labor intensity.

It can be combined with other conveying equipment (such as pipelines, valves, etc.) to form a complete conveying system. The conveying mode is flexible and diverse, and it can be unloaded at a single point or at multiple points to meet different conveying requirements.

Suction type pneumatic conveying bin pump

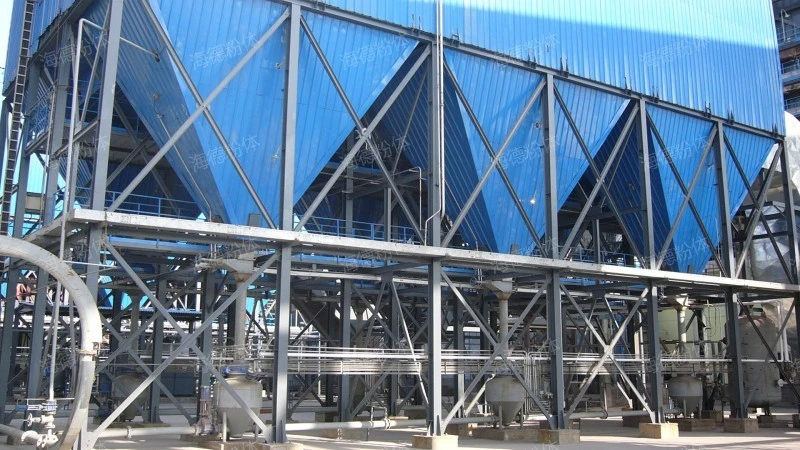

3、Suction type pneumatic conveying bin pump HD real shot

You can buy Suction type pneumatic conveying bin pump according to your needs and show you product videos.。

Suction type pneumatic conveying bin pump

As you can see from the live video.,Shandong Haide Fenti Engineering Co., Ltd. The overall structural design is relatively simple,it is mainly composed of air evacuation valve, fluidizer, control system, bleeder valve and air evacuation valve。

4、Suction type pneumatic conveying bin pump display

HD pictures of Suction type pneumatic conveying bin pump of different specifications and models。

Suction type pneumatic conveying bin pump

Note: All the pictures in this article were taken by hyde manufacturer.。

5、Introduction of Suction type pneumatic conveying bin pump characteristics

Suction type pneumatic conveying bin pumpit has the characteristics of efficient transportation, simple operation, high reliability, omniseal and flexible layout,multifunctional, with functions such as pneumatic transport, particle transport, material handling, pneumatic transport and powder conveying,is a kind of high quality and low price Suction type pneumatic conveying bin pump,support customization。

Suction type pneumatic conveying bin pump

6、Advantages of Suction type pneumatic conveying bin pump principle

The Suction type pneumatic conveying bin pump has the following principles.

- Conveying stage

- Feeding stage

- Discharge stage

- Conveying stage

- Feeding stage

When the material in the pump body reaches a certain amount, the feed valve is closed. Then, introduce compressed air into the pump body. The compressed air expands rapidly in the pump body, so that the material is fully mixed with the air, and the material is pushed along the conveying pipeline under the action of air pressure.

The feed valve of the Suction type pneumatic conveying bin pump is opened, and the material enters the pump body of the Suction type pneumatic conveying bin pump under the action of gravity or other feeding devices. In this process, the pressure inside the pump body is basically the same as the external atmospheric pressure to ensure the smooth entry of materials.

After the material is transported to the destination, it is discharged through the discharge valve. The destination can be a silo, a reaction kettle and other equipment for receiving materials. After discharging, the whole Suction type pneumatic conveying bin pump system can enter the next feeding-conveying-discharging cycle.

When the material in the pump body reaches a certain amount, the feed valve is closed. Then, introduce compressed air into the pump body. The compressed air expands rapidly in the pump body, so that the material is fully mixed with the air, and the material is pushed along the conveying pipeline under the action of air pressure.

The feed valve of the Suction type pneumatic conveying bin pump is opened, and the material enters the pump body of the Suction type pneumatic conveying bin pump under the action of gravity or other feeding devices. In this process, the pressure inside the pump body is basically the same as the external atmospheric pressure to ensure the smooth entry of materials.

Suction type pneumatic conveying bin pump

Suction type pneumatic conveying bin pumpis a common Suction type pneumatic conveying bin pump,it has the characteristics of high reliability, omniseal, simple operation, meet the requirements of environmental protection and simple operation,It is mostly used in pneumatic ash conveying, particle transport, material handling, powder conveying, pneumatic ash conveying, environmental protection and dust removal and so on。

Related recommendation

-

What is a Lithium manganese oxide transportation? Powder conveying specifications, models, and parameters

2025-5-26 -

Introduction to Dry desulfurization system and pneumatic conveying system structure principle

2025-5-26 -

Introduction to Polypropylene pneumatic conveying, advantages, characteristics and principles of Material conveying

2025-5-26 -

Introduction to Aluminum powder pneumatic conveying system, Pneumatic conveying equipment advantages, characteristics and principles

2025-5-26 -

What is a Powder electrolyte conveying system? Introduction to the advantages and characteristics of pneumatic conveying functions

2025-5-26 -

What is a Silicon dioxide conveying equipment? Powder pneumatic conveying specifications, models, and parameters

2025-5-26 -

What is a Pneumatic conveying Roots vacuum pump unit? Introduction to the advantages and characteristics of the Roots Blower

2025-5-26 -

Introduction to Weighing and conveying and Pneumatic conveying equipment advantages and features

2025-5-26 -

What is a Wood gas pressurized Roots blower? Introduction to the advantages and characteristics of the Roots Blower

2025-5-26 -

Introduction to Lithium battery positive electrode material conveying equipment, Pneumatic conveying equipment specifications, model parameters

2025-5-26