Introduction to Double stage parallel three blade Roots vacuum pump and Three leaf Roots blower structure principle

Double stage parallel three blade Roots vacuum pumpis a double impeller synchronous compression machine, belonging to a positive displacement blower.。

1、Brief introduction of Double stage parallel three blade Roots vacuum pump

Double stage parallel three blade Roots vacuum pumpis an efficient volumetric gas conveying and pressurizing equipment.,support customization。

Double stage parallel three blade Roots vacuum pump

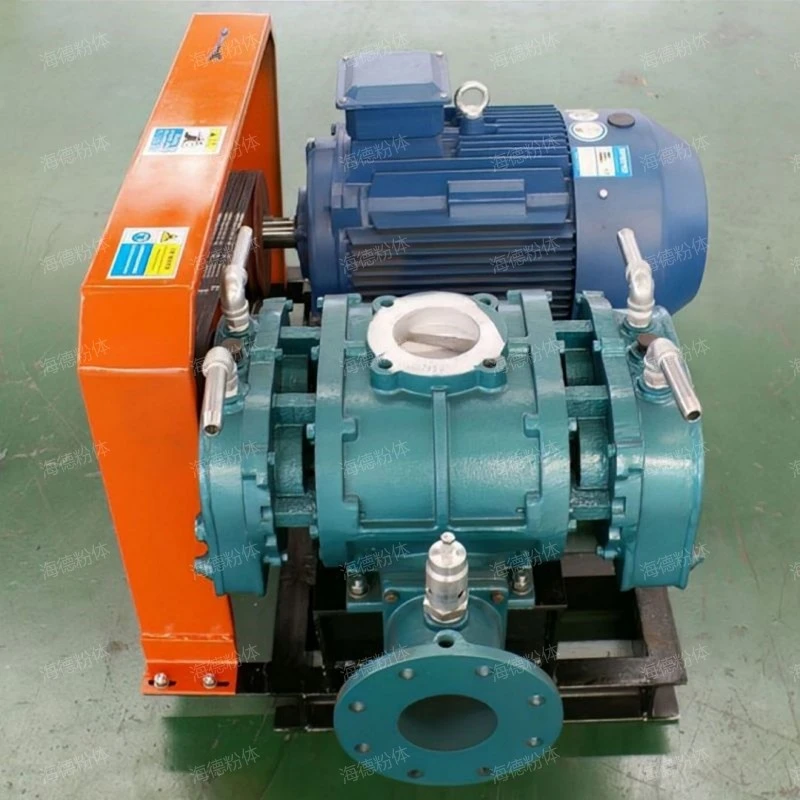

2、Double stage parallel three blade Roots vacuum pump HD real picture

Double stage parallel three blade Roots vacuum pump picture at a glance, showing elegance.。

Double stage parallel three blade Roots vacuum pump

Note: All the pictures in this article were taken by hyde manufacturer.。

3、Introduction of Double stage parallel three blade Roots vacuum pump characteristics

Double stage parallel three blade Roots vacuum pumpsmooth operation,energy-efficient,convenient maintenance,durable performance,run smoothly,multifunctional, with functions such as pressurized transportation, dry, aeration, aquaculture and exhaust emission,the main structure includes wallboard, impeller, bearing, fuel tank, impeller and so on,Double stage parallel three blade Roots vacuum pumpThe overall structural design is simple, diverse and beautiful.。

Double stage parallel three blade Roots vacuum pump

4、Structural characteristics of Double stage parallel three blade Roots vacuum pump

The Double stage parallel three blade Roots vacuum pump has the following structure

- muffler

- impeller

- rotator

- fuel tank

- case

Used to reduce the noise caused by airflow pulsation when the Double stage parallel three blade Roots vacuum pump enters and exits.

It is the rotating part of the Double stage parallel three blade Roots vacuum pump, which is divided into two leaves and three leaves. However, due to many advantages such as smaller air pulsation, less noise and smoother operation, the three-leaf Double stage parallel three blade Roots vacuum pump has gradually replaced the two-leaf Double stage parallel three blade Roots vacuum pump.

The core components are two identical lobed rotors, which usually adopt involute or epicycloid envelope design to ensure close cooperation during rotation and reduce leakage.

Mainly used for storing lubricating oil used for lubricating gears and bearings. The oil tank is used to store lubricating oil to lubricate bearings and gears and reduce wear and friction.

It mainly plays the role of supporting (wallboard, impeller, muffler) and fixing. The casing is the external structure of the Double stage parallel three blade Roots vacuum pump, which is used to support and fix the rotor, bearings and other components, while ensuring the gas tightness.

Double stage parallel three blade Roots vacuum pump

5、Advantages of Double stage parallel three blade Roots vacuum pump principle

Double stage parallel three blade Roots vacuum pumpat runtime,The two three-blade impellers rotate relatively in the space sealed by the casing and the wallboard. Each impeller adopts the envelope of involute or epicycloid, the three blades of each impeller are exactly the same, and the two impellers are also exactly the same, which greatly reduces the machining difficulty. During the rotation of the impeller, air enters the air inlet cavity under the action of atmospheric pressure, and then two blades of each impeller, the wallboard and the casing form a sealed cavity. During the rotation of the impeller, the air in the air inlet cavity is continuously brought to the exhaust cavity by the sealed cavity formed by the two blades, and because the impellers in the exhaust cavity are meshed with each other, the air between the two blades is squeezed out, so that the air is continuously transported from the air inlet to the air outlet.,the advantage is The structural form of the three-blade rotor and the reasonable structure of the air inlet and outlet in the shell make the fan have small vibration and low noise.、Due to the adoption of synchronous gear transmission and small gap design, the Double stage parallel three blade Roots vacuum pump runs stably and reliably, without contact and wear parts, and has a long service life.、It has high efficiency and can realize gas transportation and pressurization with low energy consumption.、The air volume is directly proportional to the rotating speed, so its air output is very stable and basically unaffected by pressure changes. This characteristic makes the Double stage parallel three blade Roots vacuum pump perform well in many situations where stable airflow is needed.、Small size and small floor space make it easy to arrange and install in places with limited space.。

Double stage parallel three blade Roots vacuum pump

Double stage parallel three blade Roots vacuum pumpis a common Double stage parallel three blade Roots vacuum pump,it has the characteristics of convenient manufacture, strong adaptability, stable and reliable, convenient manufacture and Precise control,the product looks atmospheric.。

Related recommendation

-

非金属矿粉气力输送

2014-3-12 -

What is a Backwash Roots blower? How much is the price of the blower?

2025-5-26 -

Introduction to Smelting plant transportation, introduction to Pneumatic conveying equipment function advantages and characteristics

2025-5-26 -

Introduction to Fermentation powder pneumatic conveying system, Powder pneumatic conveying specifications, model parameters

2025-5-26 -

CMC羧甲基纤维素气力输送

2014-3-9 -

What is a HDSR350 Roots blower? Introduction to the principle of Roots Blower structure

2025-5-26 -

Introduction to Quartz conveying equipment, how much is the price of the Powder pneumatic conveying?

2025-5-26 -

Introduction to Gypsum powder ash pneumatic conveying equipment, how much is the price of the Powder conveying?

2025-5-26 -

Introduction to Quantitative weighing and conveying, Powder pneumatic conveying advantages, characteristics and principles

2025-5-26 -

Introduction to Positive and negative pressure hybrid pneumatic conveying system, how much is the price of the Pneumatic conveying equipment?

2025-5-26