What is a Reverse flow cooling Roots vacuum pump equipment? Introduction to the advantages, characteristics, and principles of the Three leaf Roots blower

Reverse flow cooling Roots vacuum pump equipmentis a positive displacement blower.,it can be used in Pharmaceutical and chemical industries, manufacturing industry, Dust removal, sewage disposal, Environmental protection industry and other industries,it has the functions of aquaculture, ventilation, aeration, supply air and pick up the suction,stable and reliable,be of simple construction,economical and durable,smooth operation,durable performance,The gas is compressed and transported by the relative rotation of a pair of trilobal rotors in the cylinder. Each trilobal rotor is supported by two bearings, and the relative position of the two rotors is always kept constant by using a pair of synchronous gears. During the rotation of the rotor, there are tiny gaps between impeller and impeller, impeller and casing, impeller and side cover, so there is no friction in the working chamber and no lubrication is needed, thus realizing the smooth transportation of gas.。The following is to introduce the Reverse flow cooling Roots vacuum pump equipment:

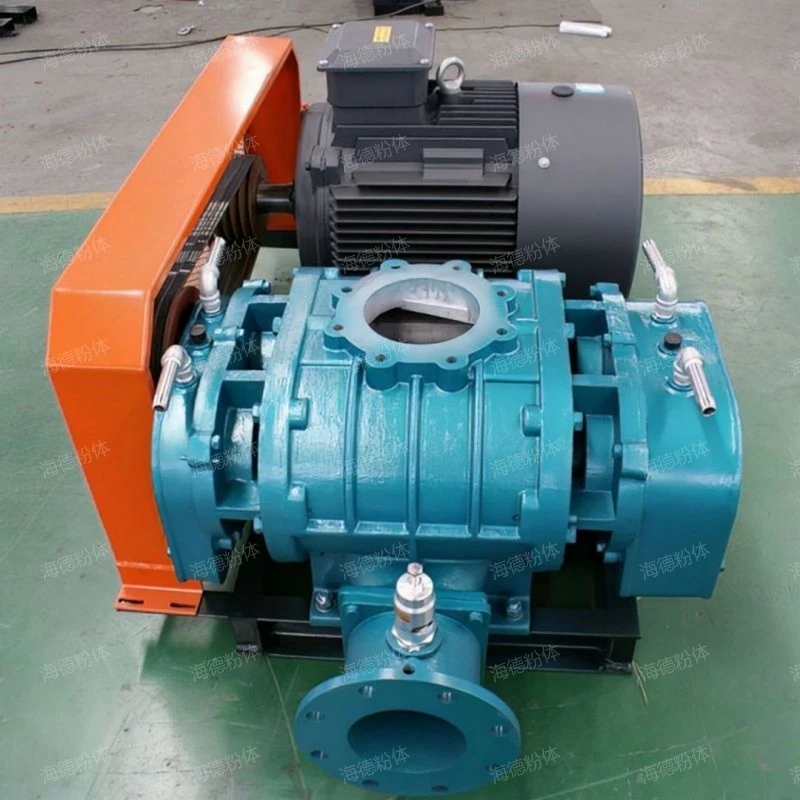

1、Brief introduction of Reverse flow cooling Roots vacuum pump equipment

Reverse flow cooling Roots vacuum pump equipmenta rotary compressor that uses two lobed rotors to move relative to each other in a cylinder to compress and transport gas.。

Reverse flow cooling Roots vacuum pump equipment

2、Video analysis of Reverse flow cooling Roots vacuum pump equipment

Speak directly with facts on the spot。

Reverse flow cooling Roots vacuum pump equipment

As you can see from the live video.,Shandong Haide Fenti Engineering Co., Ltd. usually used in aquaculture, Flue gas treatment, chemical fertilizer, mine, Textile light textile and other fields。

3、Reverse flow cooling Roots vacuum pump equipment structure

The Reverse flow cooling Roots vacuum pump equipment structure is introduced as follows:

- case

- rotator

- bearing

- fuel tank

- impeller

It mainly plays the role of supporting (wallboard, impeller, muffler) and fixing. The casing is the external structure of the Reverse flow cooling Roots vacuum pump equipment, which is used to support and fix the rotor, bearings and other components, while ensuring the gas tightness.

The core components are two identical lobed rotors, which usually adopt involute or epicycloid envelope design to ensure close cooperation during rotation and reduce leakage.

It is used to support the rotation of the rotor and bear the weight of the rotor and the load during operation.

Mainly used for storing lubricating oil used for lubricating gears and bearings. The oil tank is used to store lubricating oil to lubricate bearings and gears and reduce wear and friction.

It is the rotating part of the Reverse flow cooling Roots vacuum pump equipment, which is divided into two leaves and three leaves. However, due to many advantages such as smaller air pulsation, less noise and smoother operation, the three-leaf Reverse flow cooling Roots vacuum pump equipment has gradually replaced the two-leaf Reverse flow cooling Roots vacuum pump equipment.

Reverse flow cooling Roots vacuum pump equipment

4、Reverse flow cooling Roots vacuum pump equipment characteristics

Reverse flow cooling Roots vacuum pump equipmentit has the characteristics of convenient manufacture, smooth operation, strong adaptability, stable and reliable and wide application range,the product looks atmospheric.,is a popular Reverse flow cooling Roots vacuum pump equipment,is an efficient volumetric gas conveying and pressurizing equipment.,Due to the adoption of synchronous gear transmission and small gap design, the Reverse flow cooling Roots vacuum pump equipment runs stably and reliably, without contact and wear parts, and has a long service life.、In the process of air intake and exhaust, the Reverse flow cooling Roots vacuum pump equipment will not produce air pulsation, which means that it does not need an additional buffer gas tank to output gas smoothly. This is particularly important for processes that require stable airflow.、Small size and small floor space make it easy to arrange and install in places with limited space.、Because of the design of three-blade rotor, the Reverse flow cooling Roots vacuum pump equipment has little vibration and low noise during operation, and the operation is stable and reliable、The structural form of the three-blade rotor and the reasonable structure of the air inlet and outlet in the shell make the fan have small vibration and low noise.。

Reverse flow cooling Roots vacuum pump equipment

5、Working principle of Reverse flow cooling Roots vacuum pump equipment

Reverse flow cooling Roots vacuum pump equipmentat work,It mainly depends on the relative movement of two lobed rotors (usually three-bladed impellers) in the cylinder to compress and transport gas.,the models are complete and can meet the needs of different users for different purposes.,features include be of simple construction, run smoothly, convenient maintenance, wide application range and durable performance,is a Reverse flow cooling Roots vacuum pump equipment,multifunctional, with functions such as exhaust emission, desulfurization oxidation, cool, pressurized transportation and material handling。

Reverse flow cooling Roots vacuum pump equipment

6、Reverse flow cooling Roots vacuum pump equipment explanation video

On-site aerial photography of Reverse flow cooling Roots vacuum pump equipment。

Reverse flow cooling Roots vacuum pump equipment

As you can see from the live video.,hyde powder the advantage is The structural form of the three-blade rotor and the reasonable structure of the air inlet and outlet in the shell make the Reverse flow cooling Roots vacuum pump equipment less vibration and noise.、Small size and small floor space make it easy to arrange and install in places with limited space.、Due to the adoption of synchronous gear transmission and small gap design, the Reverse flow cooling Roots vacuum pump equipment runs stably and reliably, without contact and wear parts, and has a long service life.、Because of the design of three-blade rotor, the Reverse flow cooling Roots vacuum pump equipment has little vibration and low noise during operation, and the operation is stable and reliable、It has high efficiency and can realize gas transportation and pressurization with low energy consumption.。

Reverse flow cooling Roots vacuum pump equipmentthe product looks beautiful.,is a device that generates positive pressure or negative pressure through the relative rotation of two impellers, thus compressing and conveying gas.,is a popular Reverse flow cooling Roots vacuum pump equipment。

Related recommendation

-

Introduction to Pneumatic material sealing pump, Material seal pump advantages, characteristics and principles

2025-5-26 -

What is a Corn feed conveying? How much is the price of the Powder pneumatic conveying?

2025-5-26 -

Introduction to Automatic metering mixed pneumatic conveying equipment, how much is the price of the Pneumatic conveying equipment?

2025-5-26 -

Introduction to Pneumatic conveying of battery negative electrode material, Powder pneumatic conveying specifications, model parameters

2025-5-26 -

What is a Special gas delivery Roots blower? Introduction to the advantages, characteristics, and principles of the Three leaf Roots blower

2025-5-26 -

What is a 316 stainless steel round mouth discharger? How much is the price of the unloader?

2025-5-26 -

Introduction to Paper mill Roots blower, advantages, characteristics and principles of Roots Blower

2025-5-26 -

What is a Silica fume conveying? Introduction to the advantages and characteristics of the Material conveying

2025-5-26 -

What is a Sulfur powder pneumatic conveying? Introduction to the Working Principle of Material conveying

2025-5-26 -

What is a Y-shaped star unloader? Introduction to the Working Principle of unloader

2025-5-26