Introduction to Low-pressure pneumatic conveying material sealing pump and Material seal pump structure principle

Low-pressure pneumatic conveying material sealing pumpIt is an advanced pneumatic conveying equipment for powder.,be loved by our customers.。

1、Brief introduction of Low-pressure pneumatic conveying material sealing pump

Low-pressure pneumatic conveying material sealing pumpIt is a new type of pneumatic conveying equipment for powder, which belongs to the category of low-pressure dilute phase conveying, and mainly uses the ejector effect of high-speed airflow to convey powder materials.,Can be continuously conveyed.,Wear is small,easy to operate,Small maintenance,Long service life,it has been widely used in building materials, medicine, glass, Thermoelectric industry, Cement industry and other industries。

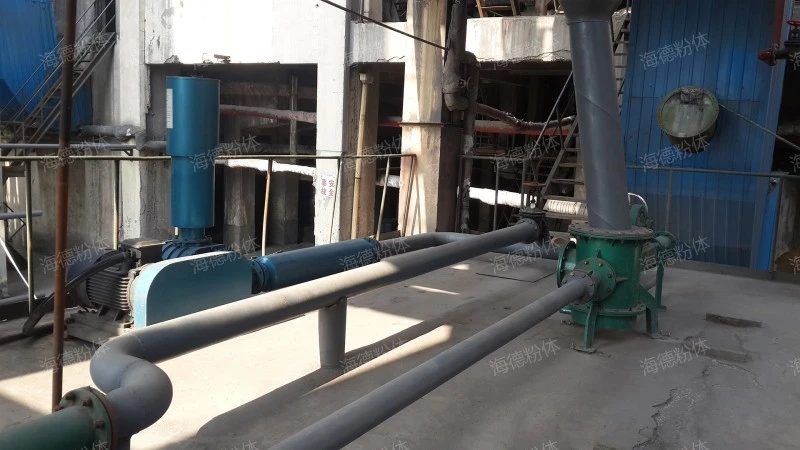

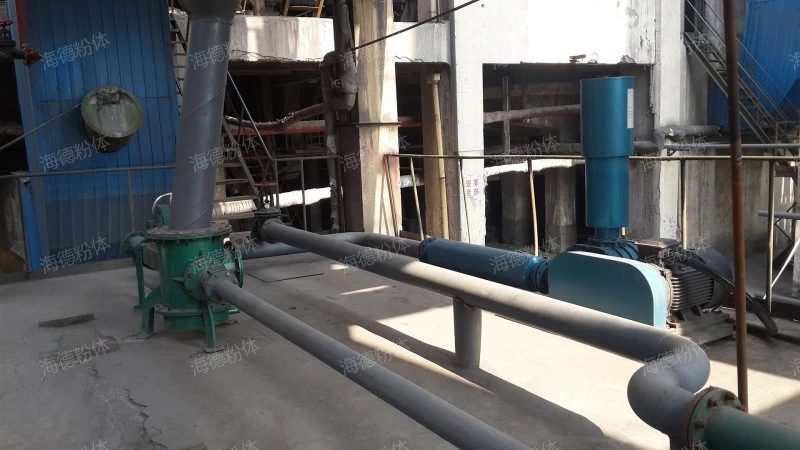

Low-pressure pneumatic conveying material sealing pump

2、Low-pressure pneumatic conveying material sealing pump function

Low-pressure pneumatic conveying material sealing pumpmultifunctional, with functions such as Long-distance or complex terrain material transportation, Raw material transportation, Waste disposal, Dust control and System supporting use,It is a product series that integrates Raw material transportation, Long-distance or complex terrain material transportation, Conveying of powdery materials, Dust control and System supporting use,the product looks atmospheric.,Can be flexibly arranged and configured according to the specific situation of the system.、Powder can be continuously conveyed, and the conveying efficiency is improved. The equipment has the function of automatically adjusting the output, which can adjust the conveying quantity according to the actual demand and achieve good ash conveying effect.、It can be transported continuously, and the output of equipment can be automatically adjusted to achieve good ash conveying effect.、It can be flexibly arranged and configured according to the specific conditions of the system to meet the transportation needs of different projects. Pipes can be arranged horizontally, vertically and obliquely, which is suitable for all kinds of complicated transportation scenes.、The low positive pressure and fully sealed conveying mode is adopted, which ensures that the powder will not leak to the external environment during the conveying process and meets the environmental protection requirements. The fully sealed design also prevents foreign substances from entering the tube, ensuring the purity and quality of the powder.,features include be of simple construction, Wear is small, Convenient and flexible layout, Transport stability and Simple operation。

Low-pressure pneumatic conveying material sealing pump

3、Structural characteristics of Low-pressure pneumatic conveying material sealing pump

The Low-pressure pneumatic conveying material sealing pump structure is introduced as follows:

- injector

- Nozzle adjusting device

- Bottom vaporization device

- Supporting and connecting parts

- Nozzle adjusting device

Nozzle is one of the key parts of the Low-pressure pneumatic conveying material sealing pump, which is responsible for generating high-speed airflow and ejecting powder materials for transportation. The design and manufacturing accuracy of the nozzle have an important influence on the performance of the Low-pressure pneumatic conveying material sealing pump.

The nozzle adjusting device is used to adjust the air outlet volume and air outlet angle of the nozzle to adapt to different conveying requirements and powder characteristics. By adjusting the nozzle adjusting device, the conveying performance of the Low-pressure pneumatic conveying material sealing pump can be optimized and the conveying efficiency and stability can be improved.

The bottom vaporizing device is an optional component in the Low-pressure pneumatic conveying material sealing pump. It vaporizes the powder at the bottom of the pump body by steam or other vaporizing media to reduce the friction and wear between the powder and the pump body and improve the smoothness and efficiency of transportation.

The supporting and connecting parts are used to support and connect various parts of the Low-pressure pneumatic conveying material sealing pump to ensure the stability and integrity of the pump body. The design and manufacture of these components need to consider factors such as strength, stiffness and stability.

The nozzle adjusting device is used to adjust the air outlet volume and air outlet angle of the nozzle to adapt to different conveying requirements and powder characteristics. By adjusting the nozzle adjusting device, the conveying performance of the Low-pressure pneumatic conveying material sealing pump can be optimized and the conveying efficiency and stability can be improved.

Low-pressure pneumatic conveying material sealing pump

4、Working principle of Low-pressure pneumatic conveying material sealing pump

Low-pressure pneumatic conveying material sealing pumpthe principle is simple.Using the high-speed airflow generated by the nozzle, a negative pressure area is formed, thereby ejecting powder materials into the pump body. This ejector action enables the powder material to be carried by the airflow and transported.,It is mostly used in Waste disposal, Raw material transportation, Long-distance or complex terrain material transportation, Conveying of powdery materials, Dust control, Conveying of powdery materials and so on,the advantage is The pressure of ash conveying medium is low, the valve of equipment pipeline is not easy to wear, and the service life is long、Using low-pressure conveying mode, the pressure of ash conveying medium is low, so the equipment pipes and valves are not easy to wear and prolong the service life.、The low positive pressure and fully sealed conveying mode is adopted, which ensures that the powder will not leak to the external environment during the conveying process and meets the environmental protection requirements. The fully sealed design also prevents foreign substances from entering the tube, ensuring the purity and quality of the powder.、Powder can be continuously conveyed, and the conveying efficiency is improved. The equipment has the function of automatically adjusting the output, which can adjust the conveying quantity according to the actual demand and achieve good ash conveying effect.、Compared with the traditional mechanical conveying mode, the pneumatic conveying mode has higher energy efficiency ratio and lower energy consumption. The fully sealed design also reduces dust emission and is beneficial to environmental protection.,is an advanced Low-pressure pneumatic conveying material sealing pump developed by our company in combination with the actual situation of the industry。

Low-pressure pneumatic conveying material sealing pump

5、Low-pressure pneumatic conveying material sealing pump characteristics

Low-pressure pneumatic conveying material sealing pumpit has the characteristics of omniseal, Reliable operation, Can be continuously conveyed., Pollution-free transportation and easy to operate,at work,Based on the ejector effect of high-speed airflow, the mixing and acceleration of airflow and powder, the formation of material column and pressure balance, the isolation and sealing of positive and negative pressure, and the automatic adjustment and adaptation.,customizable。

Low-pressure pneumatic conveying material sealing pump

Low-pressure pneumatic conveying material sealing pumpit has the functions of Long-distance or complex terrain material transportation, System supporting use, Waste disposal, Dust control and Conveying of powdery materials,It has the functions of Long-distance or complex terrain material transportation, Waste disposal, System supporting use, Waste disposal and Dust control。

Related recommendation

-

What is a Factory Lushi fan? Introduction to the advantages and characteristics of blower functions

2025-5-26 -

Introduction to Metal iron powder pneumatic conveying, Pneumatic conveying equipment specifications, model parameters

2025-5-26 -

硫酸钙气力输送案例

2014-3-14 -

What is a Three leaf Roots blower in the foundry industry? Introduction to the principle of Roots Blower structure

2025-5-26 -

Introduction to Pneumatic dust removal, Powder conveying advantages, characteristics and principles

2025-5-26 -

Introduction to Roots vacuum pump system, introduction to Roots Blower advantages and characteristics

2025-5-26 -

土霉素气力输送

2014-3-11 -

What is a Domestic feeder? How much is the price of the Feeder?

2025-5-26 -

Introduction to Dry sand conveying equipment, introduction to pneumatic conveying advantages and characteristics

2025-5-26 -

What is a Pharmaceutical particle pneumatic conveying system? Introduction to the Working Principle of pneumatic conveying system

2025-5-26