Introduction to Direct blowing powder conveying pump, bin pump advantages, characteristics and principles

Direct blowing powder conveying pumpis a kind of equipment used for pneumatic conveying, which is mainly used to convey powdery or granular materials to designated places through airflow.,simple operation,omniseal,large conveying capacity,convenient maintenance,efficient transportation,it can be used in electricity industry, electricity industry, Cement industry, grain processing, Building materials industry and other industries,is based on hyde powder is a kind of Direct blowing powder conveying pump manufactured by hyde。

1、Brief introduction of Direct blowing powder conveying pump

Direct blowing powder conveying pumpas an efficient pneumatic conveying equipment,the product looks beautiful.,When the material enters the pump body and is full, it is gasified to make the material form a fluidized state and smoothly enter the mixing chamber. At the same time, the compressed air is ejected at high speed through the jet nozzle and fully mixed with the fluid material. The high-speed airflow drives the material to pass through a specific pipeline, which converts the kinetic energy of compressed air into pressure energy, and at the same time, the air and the material are mixed again, so as to improve the speed of the material and make it move forward along the conveying pipeline, thus achieving the purpose of conveying powdery materials.,Widely used inpowder conveying,particle transport,pneumatic transport,environmental protection and dust removal,environmental protection and dust removal and so on,it has the functions of material handling, pneumatic ash conveying, pneumatic transport, environmental protection and dust removal and material handling。

Direct blowing powder conveying pump

2、Direct blowing powder conveying pump principle

Direct blowing powder conveying pumpat work,It is a part of positive pressure pneumatic ash removal system to transport loose materials such as powder and granule through pipelines in a long distance and with high efficiency.,The price is low and affordable。

Direct blowing powder conveying pump

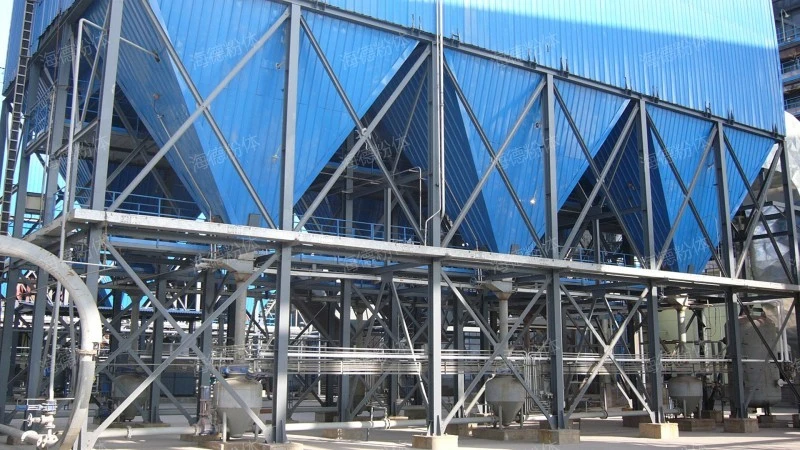

3、Direct blowing powder conveying pump picture

High-definition pictures of hyde powder Direct blowing powder conveying pump, showing different specifications and models.。

Direct blowing powder conveying pump

Note: All the pictures in this article were taken by hyde manufacturer.。

4、Direct blowing powder conveying pump function

Direct blowing powder conveying pumpmultifunctional, with functions such as pneumatic ash conveying, powder conveying, particle transport, particle transport and pneumatic ash conveying。

Direct blowing powder conveying pump

5、Advantages of Direct blowing powder conveying pump principle

The principle of Direct blowing powder conveying pump is introduced as follows:

- Feeding stage

- Conveying stage

- Feeding stage

- Discharge stage

- Conveying stage

The feed valve of the Direct blowing powder conveying pump is opened, and the material enters the pump body of the Direct blowing powder conveying pump under the action of gravity or other feeding devices. In this process, the pressure inside the pump body is basically the same as the external atmospheric pressure to ensure the smooth entry of materials.

When the material in the pump body reaches a certain amount, the feed valve is closed. Then, introduce compressed air into the pump body. The compressed air expands rapidly in the pump body, so that the material is fully mixed with the air, and the material is pushed along the conveying pipeline under the action of air pressure.

The feed valve of the Direct blowing powder conveying pump is opened, and the material enters the pump body of the Direct blowing powder conveying pump under the action of gravity or other feeding devices. In this process, the pressure inside the pump body is basically the same as the external atmospheric pressure to ensure the smooth entry of materials.

After the material is transported to the destination, it is discharged through the discharge valve. The destination can be a silo, a reaction kettle and other equipment for receiving materials. After discharging, the whole Direct blowing powder conveying pump system can enter the next feeding-conveying-discharging cycle.

When the material in the pump body reaches a certain amount, the feed valve is closed. Then, introduce compressed air into the pump body. The compressed air expands rapidly in the pump body, so that the material is fully mixed with the air, and the material is pushed along the conveying pipeline under the action of air pressure.

Direct blowing powder conveying pump

6、hyde powder service

It takes a long time to buy the product back, and if the after-sales service is not guaranteed, it will also produce higher expenses. Therefore, when purchasing the Direct blowing powder conveying pump, we should pay special attention to the after-sales situation of the manufacturer. hyde provides customers with perfect pre-sale, in-sale and after-sale services, completely dispelling customers' worries and enjoying hyde powder's full-station service experience with peace of mind.。

hyde

Direct blowing powder conveying pumpit has the characteristics of automation, environmental protection and energy saving, high reliability, meet the requirements of environmental protection and flexible layout,it has the functions of material handling, pneumatic transport, powder conveying, environmental protection and dust removal and material handling。

Related recommendation

-

What is a Dust free closed pneumatic conveying equipment? Introduction to the advantages and characteristics of the pneumatic conveying system

2025-5-26 -

What is a Intelligent conveying? Introduction to the Working Principle of pneumatic conveying system

2025-5-26 -

Introduction to Negative pressure self-priming pneumatic conveying equipment, Powder pneumatic conveying specifications, model parameters

2025-5-26 -

Introduction to Unmanned feeding pneumatic conveying, advantages, characteristics and principles of Material conveying

2025-5-26 -

What is a Upward suction powder conveying pump? Introduction to the Working Principle of bin pump

2025-5-26 -

What is a Positive pressure bin pump pneumatic conveying? Introduction to the advantages and characteristics of pneumatic conveying functions

2025-5-26 -

What is a Water cooled three blade Roots blower? Introduction to the principle of Three leaf Roots blower structure

2025-5-26 -

What is a Electronic Factory Conveyor? Introduction to the advantages and characteristics of Material conveying functions

2025-5-26 -

Introduction to Three leaf Roots blower for paper industry, how much is the price of the blower?

2025-5-26 -

What is a Coal ash pneumatic conveying? Introduction to the advantages, characteristics, and principles of the Powder pneumatic conveying

2025-5-26